Agricultural waste generates methane gas – a potent energy source Canadian farmers are rapidly turning organic waste into profit. Through natural decomposition, organic materials like livestock manure, crop residues, and food processing waste release biogas containing 50-70% methane, along with carbon dioxide and trace gases. This renewable fuel source powers thousands of Canadian farms while reducing greenhouse gas emissions and creating new revenue streams. As energy costs rise and environmental regulations tighten, understanding and harnessing agricultural methane production has become essential for modern farming operations. Whether you manage a small family farm or large agricultural enterprise, implementing biogas capture systems can transform waste management challenges into sustainable opportunities. This practical guide explores the science behind agricultural gas production and provides proven strategies for Canadian farmers to effectively collect, process and monetize this valuable byproduct.

The Science Behind Agricultural Biogas

Key Gas Components

Agricultural waste breakdown primarily produces two key gases: methane (CH4) and carbon dioxide (CO2). In typical biogas composition, methane makes up about 50-70% of the total volume, while carbon dioxide accounts for 30-40%. These percentages can vary based on factors like feedstock type and decomposition conditions.

Methane is the most valuable component, as it’s the primary energy-producing gas that can be captured and used for heat and power generation. Here in Alberta, many farms are already harnessing this potential, with methane from dairy and hog operations powering farm equipment and heating buildings.

Carbon dioxide, while often considered just a byproduct, actually plays a crucial role in the anaerobic digestion process. Some innovative Canadian farmers are capturing this CO2 for greenhouse operations, creating a complete circular system on their farms.

Other trace gases present in smaller amounts include hydrogen sulfide, nitrogen, and water vapour. While these make up less than 1% of the total composition, proper management of these components is essential for efficient biogas utilization and system maintenance.

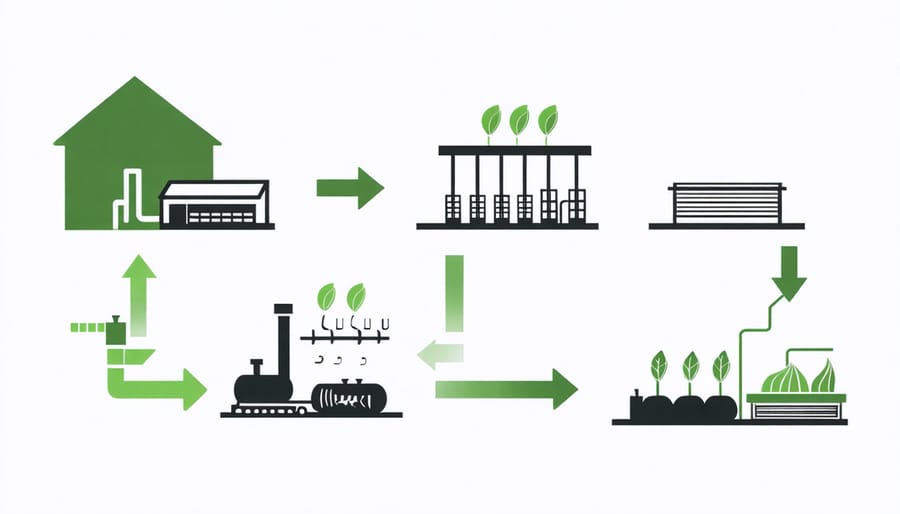

The Anaerobic Digestion Process

The anaerobic digestion process turns agricultural waste into valuable biogas through four main stages. First, during hydrolysis, bacteria break down complex organic materials like crop residues and manure into simpler compounds. Picture it as nature’s way of preparing ingredients for a recipe.

In the second stage, acidogenic bacteria convert these simple compounds into volatile fatty acids, alcohols, and gases like carbon dioxide and hydrogen. This acidogenesis stage is where the real transformation begins.

Next comes acetogenesis, where the products from the previous stage convert into acetic acid, hydrogen, and carbon dioxide. Think of this as the final prep work before the main event.

Finally, during methanogenesis, specialized bacteria called methanogens convert these compounds into biogas. The result is typically 60-70% methane and 30-40% carbon dioxide, with trace amounts of other gases. The whole process takes about 20-30 days under ideal conditions of 35-38°C.

For optimal results, maintaining consistent temperature and pH levels is crucial. Here in Alberta, many farmers are successfully using insulated digesters to keep the process running smoothly year-round, even during our cold winters.

Agricultural Sources of Biogas in Alberta

Livestock Manure

Livestock manure represents one of the largest sources of agricultural gas emissions in Canada, particularly on Alberta’s cattle operations. When properly managed, however, these emissions can become valuable resources within circular agricultural practices.

The primary gases produced from livestock manure include methane (CH4), carbon dioxide (CO2), and small amounts of nitrous oxide (N2O). Methane, which has the highest concentration, is generated when organic matter decomposes in oxygen-free environments, such as manure storage facilities and lagoons.

On a typical Alberta dairy farm with 200 cows, manure production can generate up to 200 cubic metres of biogas daily. This biogas typically contains 60-65% methane, making it an excellent energy source when captured properly. Many progressive farmers are now installing anaerobic digesters to harness this potential.

The amount of gas produced varies depending on several factors:

– Animal type and size

– Feed quality and composition

– Manure collection method

– Storage conditions

– Ambient temperature

Modern manure management systems can capture these gases for on-farm energy production, reducing both emissions and operating costs. Several Alberta farms have successfully implemented these systems, with some producing enough energy to power their entire operations and sell excess to the grid.

Crop Residues

Crop residues represent a significant untapped resource on Canadian farms, with the potential to generate valuable biogas through anaerobic digestion. When crop remnants like straw, corn stalks, and chaff decompose in oxygen-free conditions, they produce a mixture of gases – primarily methane and carbon dioxide.

Here in Alberta, many farmers are discovering the dual benefit of managing crop waste while producing renewable energy. For example, the Lethbridge Biogas facility processes over 100,000 tonnes of agricultural waste annually, converting what would otherwise be unused biomass into clean energy.

The process begins by collecting and storing crop residues after harvest. These materials are then mixed with other organic waste and fed into anaerobic digesters, where naturally occurring bacteria break down the organic matter. The resulting biogas typically contains 50-70% methane, which can be used for heating, electricity generation, or even upgraded to natural gas quality.

One hectare of crop residue can generate approximately 2,000 to 3,000 cubic metres of biogas annually. This represents not only a solution for waste management but also a potential income stream for farmers. Many agricultural operations across Alberta are now incorporating biogas systems into their sustainability plans, helping reduce greenhouse gas emissions while creating renewable energy from what was once considered waste material.

Benefits for Canadian Farmers

Revenue Generation

Biogas production from agricultural waste presents significant revenue opportunities for Canadian farmers. A typical mid-sized dairy farm with 200 cattle can generate between $75,000 to $120,000 annually through biogas sales and reduced energy costs. Many Alberta farmers have successfully integrated biogas systems, selling excess electricity back to the grid through the province’s micro-generation program.

Beyond direct energy sales, farmers can create additional revenue streams through carbon credit programs and the sale of digestate as organic fertilizer. The Alberta Carbon Offset System currently offers around $30 per tonne of CO2 equivalent reduced, making biogas projects increasingly attractive from a financial standpoint.

Several grant programs support initial setup costs, including the Agricultural Clean Technology Program, which can cover up to 50% of project expenses. The return on investment typically ranges from 3-7 years, depending on system size and efficiency. Local success stories, like the Lethbridge Biogas facility, demonstrate how collaborative approaches between multiple farms can maximize profitability while sharing infrastructure costs.

Remember to consult with agricultural financial advisors to explore funding options and develop a sustainable business model for your biogas operation.

Environmental Impact

Agricultural gas byproducts present both challenges and opportunities for Canadian farmers committed to carbon footprint reduction. When managed properly, these gases can become valuable resources in sustainable farming practices. For example, methane captured from manure management systems can be converted into renewable energy, powering farm operations and reducing reliance on fossil fuels.

In Alberta, innovative farmers are leading the way by implementing integrated waste-to-energy systems that transform what was once considered a liability into an asset. These systems not only minimize greenhouse gas emissions but also create additional revenue streams through energy generation and organic fertilizer production.

Recent studies from Prairie agricultural research stations show that proper management of agricultural gas byproducts can reduce a farm’s overall emissions by up to 30%. This reduction comes alongside improved soil health and water quality, demonstrating that environmental stewardship and productive farming can go hand in hand.

By adopting these practices, Canadian farmers are positioning themselves as environmental leaders while maintaining competitive and sustainable operations for future generations.

Implementation Success Stories

The Lethbridge Biogas facility stands as a shining example of agricultural innovation in Alberta. Since its establishment in 2013, this facility has successfully converted livestock manure and organic waste into renewable energy, processing over 120,000 tonnes of agricultural byproducts annually. The project has not only reduced greenhouse gas emissions but has also created new revenue streams for local farmers who supply the facility with organic waste.

Prairie Gold Farms in Red Deer County demonstrates how smaller operations can benefit from biogas systems. Owner James Morrison implemented a modest-scale digester in 2018, which now processes waste from his 200-head dairy operation. “The system pays for itself through energy savings and additional income from excess power sales to the grid,” Morrison explains. His farm has achieved a remarkable 40% reduction in energy costs while earning additional revenue through Alberta’s sustainability certification program.

The Bow Valley Agricultural Cooperative presents another compelling success story. This collective of fifteen farms pooled resources to establish a community-scale biogas facility in 2019. The cooperative approach made the project financially viable for smaller farms that couldn’t afford individual systems. Today, the facility processes agricultural waste from all member farms, generating enough electricity to power 500 homes while producing high-quality fertilizer as a beneficial by-product.

These success stories share common elements: careful planning, community collaboration, and strategic partnerships with technology providers. The projects have demonstrated that biogas systems can be scaled to suit different operation sizes, from individual farms to regional facilities. They’ve also shown that with proper management, these systems can provide multiple benefits: waste management solutions, renewable energy production, and new income opportunities for Alberta’s agricultural community.

The measurable impacts are impressive: collectively, these three projects prevent the release of approximately 50,000 tonnes of methane annually into the atmosphere while generating sustainable energy and creating valuable agricultural inputs. Their success has inspired similar initiatives across the province, with twelve new biogas projects currently in various stages of development.

Taking the first step toward biogas production on your farm doesn’t have to be overwhelming. Start by conducting a waste assessment to determine your farm’s biomass potential – this includes calculating your livestock manure output, crop residues, and other organic waste materials. Next, connect with local agricultural extension offices or renewable energy consultants who can help evaluate your farm’s specific needs and potential.

Consider forming partnerships with neighbouring farms to share resources and costs. Many successful biogas operations in Alberta began as cooperative ventures, making the initial investment more manageable. The Canadian Agricultural Partnership offers grants and funding programs that can help offset setup costs – reach out to your provincial agricultural office for current opportunities.

Begin small with a pilot project or scaled system that can be expanded later. Install gas monitoring equipment to track production levels and efficiency. Remember to maintain detailed records of your waste inputs and gas outputs – this data will be invaluable for optimizing your system.

Join local farming networks and biogas associations to learn from others’ experiences. The Canadian Biogas Association offers resources and connects farmers with experts in the field. Consider hosting farm tours once your system is operational to share knowledge with other interested farmers in your community.

Most importantly, develop a solid maintenance plan and train your staff properly. Success in biogas production comes from consistent operation and monitoring, making it a sustainable part of your farm’s future.