Transform your farm’s waste into clean energy through biogas production, joining the growing community of Canadian farmers who generate sustainable power from manure. Each day, a typical 200-cow dairy operation produces enough manure to power 40 homes, presenting a remarkable opportunity to reduce operational costs while contributing to environmental sustainability. Alberta farmers are uniquely positioned to leverage this technology, with abundant feedstock and supportive provincial initiatives making biogas production increasingly accessible and profitable. The conversion of manure to biogas not only addresses waste management challenges but also creates multiple revenue streams through electricity generation, carbon credit opportunities, and the production of high-quality organic fertilizer. This practical solution transforms a daily agricultural challenge into a valuable farm asset, delivering both environmental and economic benefits to Canadian agricultural operations.

Why Manure-Based Biogas Makes Sense for Alberta Farms

Environmental Benefits

Converting manure into biogas offers substantial environmental advantages for Alberta farms and our broader ecosystem. One of the most significant benefits is the reduction of methane emissions from traditional manure storage methods. When manure decomposes in open-air lagoons or stockpiles, it releases methane, a greenhouse gas 25 times more potent than carbon dioxide. By capturing this methane through biogas production, farms can achieve significant carbon footprint reduction.

The process also improves waste management practices on farms. Instead of dealing with raw manure storage and disposal challenges, biogas systems transform this waste into valuable resources. The digestate byproduct serves as an enhanced fertilizer, reducing the need for synthetic alternatives and creating a more sustainable nutrient cycle on the farm.

Water quality benefits are another key advantage, as proper manure management through biogas systems helps prevent nutrient runoff into local waterways. This protection of our water resources is particularly important for Alberta’s agricultural communities, where watershed health directly impacts both farming operations and local ecosystems. The system effectively closes the loop in farm waste management, turning what was once considered a disposal challenge into an environmentally sound opportunity.

Economic Advantages

Converting manure into biogas offers substantial financial benefits for Alberta farmers. Recent studies show that a mid-sized dairy farm with 200 cattle can save $15,000 to $25,000 annually on energy costs through biogas production. Beyond cost savings, farmers can generate additional revenue by selling excess electricity back to the grid through Alberta’s Micro-Generation Regulation.

The initial investment is offset by various government incentives. The Canadian Agricultural Clean Technology Program offers funding up to $2 million for biogas projects, while Alberta’s Emissions Reduction Alberta (ERA) provides matching grants of up to 50% of project costs. These programs significantly reduce the financial barrier to entry.

Many Alberta farmers report achieving ROI within 5-7 years, particularly when combining biogas production with existing operations. Additional economic advantages include reduced fertilizer costs through the use of digestate, lower waste management expenses, and potential carbon credit revenue through Alberta’s carbon offset system.

Local success stories, like the Lethbridge Biogas facility, demonstrate how manure-to-biogas projects can create new income streams while solving waste management challenges. The facility generates over $500,000 annually from electricity sales alone.

Setting Up Your Farm’s Biogas System

Basic Infrastructure Requirements

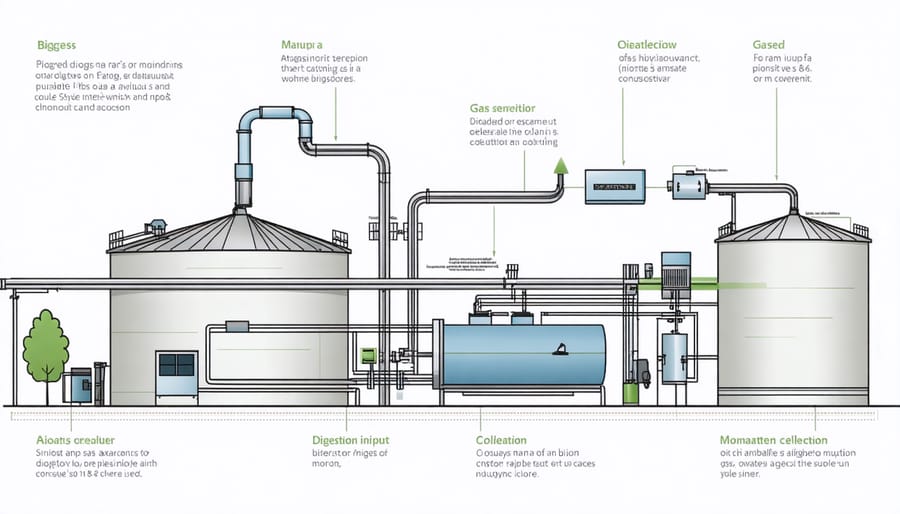

Setting up a biogas system requires careful planning and specific infrastructure components. At its core, you’ll need a manure collection system, which typically includes concrete pads and gutters to efficiently gather and transport manure to the digester. The main component is the anaerobic digester tank, usually constructed from concrete or steel, with proper insulation to maintain optimal temperatures in Alberta’s climate.

The system requires a gas collection and storage unit, typically a flexible membrane cover or separate storage tank, to safely contain the produced biogas. A mixer or agitation system is essential to prevent settling and maintain consistent digestion. You’ll also need temperature control mechanisms, crucial for our northern climate, including heating coils or hot water pipes within the digester.

As part of modern circular agricultural practices, monitoring equipment is vital, including temperature sensors, gas meters, and pH monitors. The setup should include a gas cleaning system to remove hydrogen sulfide and moisture, protecting your equipment and ensuring efficient energy production.

Don’t forget the basics: proper piping systems, safety valves, and a flare system for excess gas management. For farms planning to generate electricity, you’ll need a generator set or combined heat and power unit. Most systems also benefit from a small control room to house monitoring equipment and electrical controls.

Remember to include adequate access roads and working space around the digester for maintenance and delivery vehicles. Having backup power systems is also crucial for maintaining operation during power outages.

Collection and Storage Systems

Proper manure collection and storage are essential first steps in successful biogas production. Here in Alberta, our varying seasonal temperatures require careful consideration of storage systems. The most effective setup typically includes a primary collection area near the barn or feedlot, connected to a pre-treatment holding tank.

For dairy and beef operations, scraper systems work well to gather manure from barn floors, while slatted floor systems are popular in pig operations. The collected manure should be transported to a receiving pit designed to handle at least one week’s worth of manure production. These pits should be concrete-lined and covered to prevent excessive rainwater dilution and reduce odour.

Storage systems come in several forms, with above-ground tanks and in-ground lagoons being the most common in our region. Tanks should be properly insulated for our climate, while lagoons need to be properly lined to prevent groundwater contamination. For optimal biogas production, maintain manure temperature between 15-20°C during storage.

Regular monitoring of moisture content is crucial – aim for 80-90% moisture for efficient biogas production. Many Alberta farmers find success using automated mixing systems to maintain consistency. Remember to include safety features like proper ventilation and gas detection systems, especially in enclosed storage areas.

To maximize efficiency, design your collection routes to minimize transport distance and consider installing a gravity-flow system where terrain permits.

Monitoring and Maintenance

Regular monitoring and maintenance are crucial for keeping your biogas system running efficiently. Key parameters to track include daily gas production rates, which should be recorded in a logbook, and methane content, which should typically range between 50-70%. Temperature monitoring is especially important during Alberta’s cold winters, with optimal digestion occurring between 35-40°C.

Check pressure gauges daily and inspect pipes for leaks weekly using soapy water solution. Pay special attention to seals and connections, particularly after freeze-thaw cycles. Monitor pH levels in the digester weekly, aiming to maintain them between 6.8-7.2 for optimal bacterial activity.

Monthly maintenance should include cleaning gas filters and checking the mixing system’s functionality. During spring and fall, conduct thorough inspections of insulation and heating systems to prepare for seasonal temperature changes. Watch for signs of foaming or crust formation in the digester, which might indicate imbalances in the biological process.

For Alberta farmers, we recommend developing a maintenance schedule that accounts for our unique climate challenges. Keep spare parts on hand, especially during winter months when deliveries might be delayed. Consider joining local biogas operator networks to share maintenance tips and experiences. Many successful operators maintain detailed maintenance logs and schedule professional inspections annually to ensure system longevity and optimal performance.

Real Success Stories from Alberta Farms

Dairy Farm Case Study

The Bergstrom Family Dairy Farm in Red Deer County, Alberta, stands as a shining example of successful biogas implementation. Operating with 200 dairy cows, the Bergstroms transformed their traditional operation into a sustainable energy powerhouse in 2019.

Before installing their biogas system, the farm struggled with manure management costs and rising energy bills. The family invested $850,000 in a complete biogas system, receiving 40% funding through Alberta’s Agricultural Clean Technology Program.

Their system processes 15 tonnes of manure daily, generating enough electricity to power their entire farm operation and three neighboring households. The excess heat from the generator maintains optimal barn temperatures year-round, significantly reducing winter heating costs.

The Bergstroms report annual savings of $45,000 on energy costs and $15,000 on fertilizer expenses, as they use the nutrient-rich digestate on their fields. The system paid for itself in just over four years, exceeding their initial projections.

“The biggest surprise wasn’t the cost savings,” says Maria Bergstrom. “It was how this system simplified our entire operation. Manure management became more efficient, and our carbon footprint dropped dramatically.”

The farm now hosts monthly tours for local farmers, sharing their experience and helping others understand the practical benefits of biogas systems in Canadian agricultural operations.

Mixed Livestock Operation Example

The Butler family farm, located just outside of Red Deer, Alberta, demonstrates how a mixed livestock operation can successfully implement a biogas system. Operating with 200 dairy cows, 500 hogs, and a seasonal poultry flock, the Butlers faced the challenge of managing diverse manure streams while seeking to reduce their environmental footprint.

In 2019, they installed a 250-kilowatt biogas system that processes approximately 30 tonnes of mixed manure daily. The system was specifically designed to handle varying consistencies of manure, using a pre-mixing tank to create a uniform slurry before digestion.

“The beauty of our setup is its flexibility,” explains Sarah Butler. “We can adjust the mixture ratios depending on what livestock we’re housing each season, and the system maintains stable gas production year-round.”

The farm now generates enough electricity to power their entire operation and sells surplus energy back to the grid. The digestate serves as a premium fertilizer for their 800 hectares of cropland, reducing their annual fertilizer costs by approximately $45,000.

The project, partially funded through Alberta’s On-Farm Energy Management Program, achieved payback within five years. The Butlers host regular farm tours, sharing their experience with other mixed livestock operators interested in biogas production. Their success demonstrates how diverse farming operations can effectively convert multiple manure streams into valuable energy and fertilizer resources.

Getting Started: Your Next Steps

Assessment and Planning

Before starting a biogas project, it’s essential to evaluate your farm’s potential and develop a solid plan. Begin by assessing your current manure production – typical dairy operations in Alberta producing 2,000 litres of milk daily generate enough manure to power 4-5 households through biogas conversion.

Calculate your farm’s total biomass availability by tracking manure output over several months. Consider seasonal variations and include other organic waste streams like crop residues or food processing waste that could supplement your feedstock.

Next, evaluate your farm’s infrastructure and space requirements. You’ll need adequate area for the digester, storage facilities, and safety buffer zones. Consider proximity to existing buildings, utilities, and road access. Most successful installations require at least 500 square metres of dedicated space.

Contact local utility providers to discuss grid connection possibilities and current energy rates. Many Alberta farmers find it helpful to consult with agricultural extension services or experienced biogas operators during this phase. Schedule a professional site assessment to analyze soil conditions, drainage patterns, and potential environmental impacts.

Remember to document everything – thorough planning now prevents costly adjustments later.

Available Resources and Support

Alberta farmers interested in implementing biogas systems can access numerous support programs and resources. The Canadian Agricultural Partnership (CAP) offers funding opportunities of up to $250,000 for sustainable agriculture initiatives, including biogas projects. Local agricultural offices provide guidance on applying for these grants and connecting with technical experts.

The Alberta Biogas Association serves as a valuable networking hub, offering workshops, training sessions, and connecting farmers with experienced biogas operators. Their mentorship program pairs new adopters with successful implementers of organic waste solutions.

Technical assistance is available through Alberta Agriculture and Forestry’s extension services, providing free consultations and feasibility studies. The Environmental Stewardship and Climate Change Producer Program offers additional funding specifically for methane reduction projects.

Local agricultural colleges, including Olds College and Lakeland College, provide hands-on training and demonstration facilities. Their expertise helps farmers understand system maintenance and troubleshooting. Remember to contact your regional agricultural fieldman for personalized guidance on available resources in your area.

As we’ve explored throughout this article, converting manure to biogas represents a significant opportunity for Alberta’s farming community. The benefits extend far beyond renewable energy production – from reducing greenhouse gas emissions and managing waste effectively to creating additional revenue streams and strengthening farm sustainability.

The success stories we’ve shared from farms across Alberta demonstrate that biogas production is not just a theoretical concept but a practical, achievable goal for operations of various sizes. With current government incentives, technical support programs, and a growing network of experienced operators, there’s never been a better time to consider implementing a biogas system on your farm.

Remember that you don’t have to tackle this journey alone. Alberta’s agricultural community is known for its collaborative spirit, and many farmers who have already implemented biogas systems are willing to share their experiences and insights. Local agricultural extension offices, renewable energy consultants, and industry associations stand ready to support your transition to biogas production.

Whether you’re starting small with a basic digester or planning a larger-scale operation, every step toward biogas adoption contributes to a more sustainable agricultural future for Alberta. We encourage you to take the next step – reach out to local resources, connect with experienced operators, and explore how biogas production could benefit your farm operation. Together, we can turn our agricultural waste into a valuable resource while building a more resilient farming community.