Transform livestock waste into a valuable farm asset by implementing circular farming principles through strategic collection, processing, and application systems. Properly managed manure reduces environmental impact while providing essential nutrients for crop production, saving Alberta farmers an average of $175 per hectare in fertilizer costs annually.

Install concrete catchment systems and covered storage facilities to capture 95% of nutrient-rich runoff, preventing groundwater contamination and maximizing nutrient retention. Modern waste management technologies, including automated scraping systems and anaerobic digesters, cut labor costs by 40% while producing renewable energy and high-quality organic fertilizer.

Design your operation’s waste handling system based on your specific livestock numbers, available land base, and soil requirements. A 100-head dairy operation typically requires 2,000 square meters of storage capacity to maintain compliance with Alberta’s Agricultural Operation Practices Act while ensuring optimal nutrient cycling throughout the year.

Partner with neighboring crop producers to establish manure-sharing agreements, creating efficient nutrient distribution networks that benefit entire farming communities while meeting organic certification requirements.

The True Value of Livestock Waste in Organic Systems

Nutrient Profiles of Different Livestock Waste Types

Different livestock species produce waste with varying nutrient profiles, making each type valuable in unique ways for Alberta farms. Cattle manure typically contains 2.5% nitrogen, 0.7% phosphorus, and 2% potassium, making it an excellent all-round fertilizer that supports soil biodiversity benefits. Poultry manure stands out with higher nutrient concentrations, containing approximately 4.5% nitrogen, 1.5% phosphorus, and 1.8% potassium, though it requires careful application due to its strength.

Pig manure offers a balanced profile with 3% nitrogen, 1% phosphorus, and 2.5% potassium, while sheep manure provides a gentle 2% nitrogen, 0.5% phosphorus, and 1.8% potassium ratio that’s particularly good for sensitive crops. Horse manure, common on many Alberta properties, contains about 1.5% nitrogen, 0.4% phosphorus, and 1.6% potassium, plus it’s excellent for improving soil structure.

These values can vary based on animal diet, bedding materials, and storage methods. Fresh manure typically has higher nutrient content than aged material, though aged manure is often easier to handle and safer to use.

Economic Benefits of Proper Waste Management

Proper livestock waste management isn’t just environmentally responsible – it’s a smart financial move for your farm. By implementing effective waste management systems, Alberta farmers typically see a 15-20% reduction in fertilizer costs through the use of processed manure. Many local farmers have reported annual savings of $5,000 to $8,000 on their fertilizer expenses alone.

Composted manure can create additional revenue streams, with quality compost selling for $30-40 per tonne in the local market. Several Alberta farms have successfully established partnerships with nearby organic vegetable growers, creating steady income from what was once considered just a waste product.

Energy generation through biogas systems, while requiring initial investment, can significantly reduce farm operating costs. The Lethbridge Biogas facility, for example, generates enough electricity to power 2,800 homes while processing agricultural waste from surrounding farms.

Collection and storage improvements can also lead to substantial water savings, with modern systems reducing water usage by up to 30%. This translates to lower utility bills and increased operational efficiency, particularly valuable during Alberta’s dry seasons.

Practical Collection and Storage Solutions

Winter-Ready Storage Systems

In Alberta’s harsh winters, proper storage of livestock waste becomes crucial for both environmental compliance and operational efficiency. Our local farmers have developed innovative solutions that work even in temperatures dropping below -30°C.

Rob Anderson, a third-generation farmer from Red Deer County, shares his success with an insulated storage system: “We’ve incorporated thick concrete walls with specialized insulation, which prevents freezing and maintains consistent decomposition rates throughout winter.”

Key features of winter-ready storage systems include:

– Double-walled containment structures with spray foam insulation

– Heated transfer pipes to prevent freezing during pumping

– Strategic placement of storage facilities to maximize solar gain

– Wind barriers to reduce heat loss and maintain optimal temperatures

The Lakeland Agricultural Research Association’s recent study demonstrates that properly insulated storage systems can maintain temperatures above 5°C even during the coldest months, ensuring continuous biological activity and proper waste breakdown.

For smaller operations, portable heated storage units have proven effective. Sarah Mitchell, from Rocky Mountain House, implemented a modular system that can be adjusted based on seasonal needs: “The flexibility allows us to manage our storage capacity while maintaining temperature control, which has been a game-changer for our winter operations.”

Regular monitoring of storage temperatures and insulation integrity helps prevent system failures. Local agricultural extension services offer free thermal imaging assessments to identify potential cold spots before they become problematic.

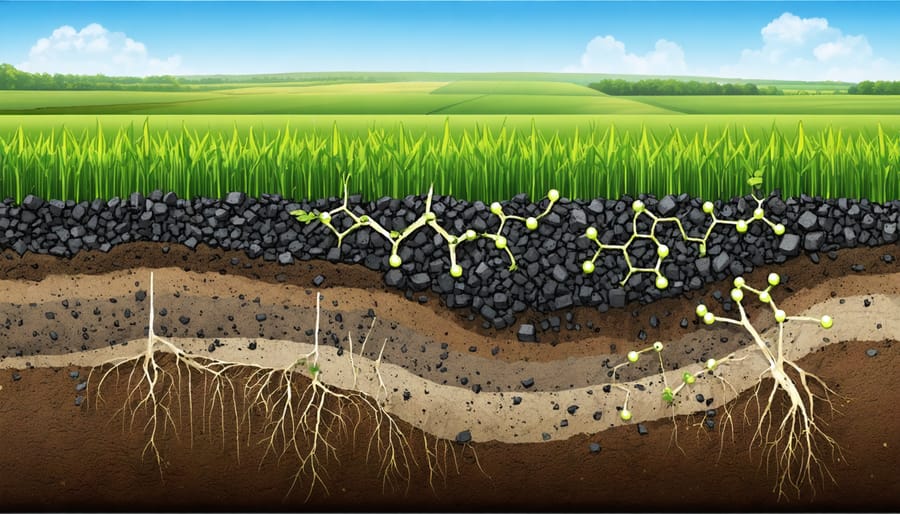

Preventing Nutrient Leaching

Maintaining nutrient quality in stored livestock waste requires careful attention to prevent leaching, which can lead to both environmental concerns and reduced fertilizer value. Here in Alberta, where we experience significant seasonal temperature variations, implementing proper storage techniques is crucial.

A well-designed storage system starts with an impermeable base layer. Consider using concrete pads with containment walls or compacted clay liners with a minimum thickness of 30 centimetres. For liquid manure storage, double-liner systems provide extra protection against seepage.

Cover your storage area to prevent rainfall from causing nutrient runoff. Options include permanent roofing structures or heavy-duty tarps. During winter months, snow management becomes particularly important – regular clearing helps maintain storage integrity and prevents spring melt issues.

Many Alberta farmers have found success using absorption materials like straw or sawdust to lock in nutrients. These materials not only help control moisture levels but also add carbon to the mix, improving the final compost quality.

Monitor moisture content regularly – aim for 50-60% moisture levels. Too wet, and you risk leaching; too dry, and you lose valuable nitrogen through ammonia volatilization. Installing proper drainage systems around storage areas helps direct any excess liquid to designated collection points.

Remember to position your storage area away from water sources and on slightly elevated ground. This simple positioning strategy can significantly reduce leaching risks while complying with local environmental regulations.

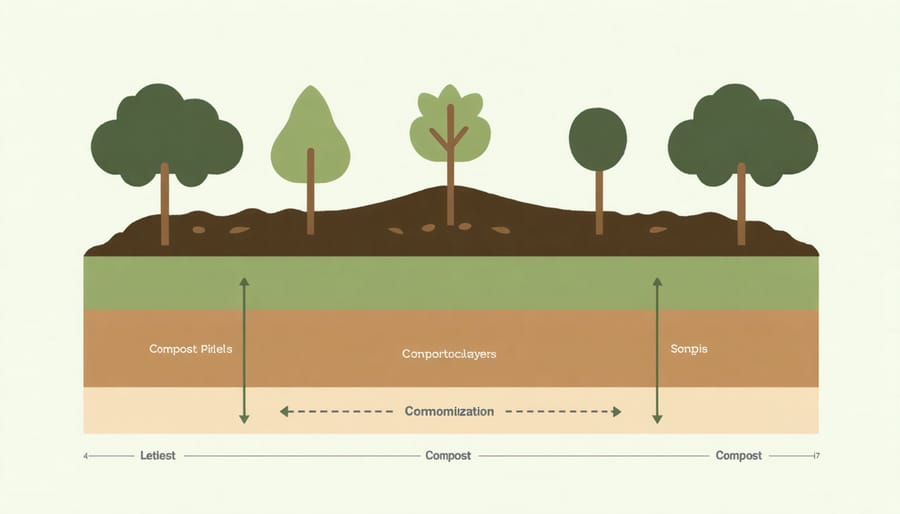

Composting Techniques for Maximum Benefit

Building the Perfect Compost Mix

Creating an effective compost mix for livestock waste requires balancing your carbon-to-nitrogen ratio, typically aiming for 30:1. Fresh manure provides nitrogen-rich materials, while bedding materials like straw and wood shavings contribute necessary carbon. For optimal results, layer your materials with approximately 60% carbon-based materials and 40% nitrogen-rich components.

Here in Alberta, we’ve found success using a mix of cattle or horse manure combined with locally available materials. Start with a 15-cm layer of coarse materials like corn stalks or wood chips for proper aeration. Add a 10-cm layer of manure, followed by a thin layer of mature compost to introduce beneficial microorganisms. Continue layering, maintaining moisture at about 50% – similar to a wrung-out sponge.

Include diverse materials when possible: hay, straw, leaves, and even vegetable scraps from your farm kitchen. Avoid meat products, dairy, or diseased plant materials. For faster decomposition, chop materials into smaller pieces before adding them to your pile. Monitor temperature regularly – a healthy pile should reach 55-65°C in its core during active composting.

Remember to turn your pile every few weeks to ensure even decomposition and maintain proper oxygen levels. In our prairie climate, covering the pile during heavy rains helps maintain optimal moisture levels while preventing nutrient leaching.

Monitoring and Maintaining Your Compost

Successful composting requires regular monitoring and maintenance to ensure optimal decomposition and nutrient retention. Check your compost’s temperature weekly using a long-stem thermometer – ideal readings should range between 54-65°C in the center of the pile. This heat indicates active decomposition and helps eliminate potential pathogens.

Moisture content is another crucial factor. Your compost should feel like a wrung-out sponge – damp but not soaking. During Alberta’s dry seasons, you might need to add water to maintain proper moisture levels. In wet periods, consider covering your pile to prevent excess water absorption.

Monitor the carbon-to-nitrogen ratio by observing the pile’s appearance and smell. A balanced compost pile should have an earthy aroma. If you notice ammonia-like smells, add more carbon-rich materials such as straw or woodchips. For slow-decomposing piles, incorporate more nitrogen-rich materials like fresh manure.

Turn your compost every 2-3 weeks to ensure even decomposition and adequate oxygen flow. This practice also helps prevent compaction and reduces odours. Keep detailed records of temperature readings, turning dates, and material additions – this information proves invaluable for improving your composting process over time.

Application Methods and Timing

Seasonal Application Guidelines

In Alberta’s unique climate, timing your livestock waste application is crucial for maximizing benefits while protecting the environment. The ideal application window typically opens in early spring, just as the ground thaws but before seeding begins, usually from late March to mid-April. This timing allows nutrients to integrate with the soil as temperatures rise.

Summer applications should be limited to avoid nutrient loss through volatilization, though early morning or evening applications during cooler hours can be effective for established crops. The sweet spot for fall application falls between harvest and ground freeze, typically from late September to early November, when soil temperatures remain above 5°C.

Avoid spreading during heavy rainfall periods or when the ground is frozen or snow-covered, as this increases runoff risk. For pasture management, allow at least three weeks between application and grazing to ensure proper decomposition and minimize health risks to livestock.

Consider your soil type when planning – sandy soils benefit from more frequent, lighter applications, while clay-based soils can handle heavier, less frequent treatments. Keep detailed records of application timing and weather conditions to optimize your schedule for future seasons and maintain compliance with local regulations.

Equipment and Application Techniques

Modern waste management equipment has revolutionized how we handle livestock waste on Canadian farms. For solid waste handling, front-end loaders and skid steers remain essential workhorses, while specialized manure spreaders offer precise application control. Box spreaders work well for solid manure, while liquid tankers equipped with injection systems are ideal for slurry application.

When applying waste to fields, timing and technique are crucial. In Alberta’s climate, spring and fall applications typically yield the best results. Consider using drag-hose systems for liquid manure application – they reduce soil compaction and provide even distribution. For precise application rates, GPS-guided systems help maintain consistent coverage while meeting nutrient management requirements.

Traditional broadcast spreading remains common, but newer incorporation methods like disc injectors and shallow tillage tools help minimize nutrient loss and odour. Many Alberta farmers have found success with subsurface deposition systems, which place manure directly into the soil.

For smaller operations, tractor-mounted spreaders offer good versatility. Regular calibration of all equipment is essential to ensure accurate application rates. Remember to maintain detailed records of application timing, rates, and field conditions – this helps optimize future applications and meets regulatory requirements.

Meeting Organic Certification Requirements

Meeting organic certification standards for livestock waste management requires careful attention to detail and proper documentation. In Canada, organic producers must demonstrate that their waste management practices protect soil and water quality while promoting nutrient cycling within the farm system.

Key requirements include maintaining buffer zones between manure storage areas and water sources, typically a minimum of 30 metres from wells or surface water. Storage facilities must be designed to prevent leaching and runoff, with proper containment systems that account for seasonal variations in precipitation.

Documentation is crucial – farmers need to maintain detailed records of waste collection, storage, and application methods. This includes tracking the source of manure, storage duration, and application rates. For composted manure, temperature logs during the composting process must be kept to verify proper pathogen reduction.

Many Alberta farmers have successfully implemented these requirements by integrating traditional farming wisdom with modern monitoring systems. For example, the Miller family farm in Central Alberta uses mobile composting units with built-in temperature monitoring, making record-keeping straightforward while ensuring compliance.

When applying manure to organic fields, timing is essential. Applications must occur at least 90 days before harvesting crops that don’t contact soil and 120 days for crops that do. This timeline helps ensure food safety while maximizing nutrient availability for crops.

Working with an organic certification body early in the planning process can help identify potential compliance issues before they become problems. Regular soil testing and maintaining detailed farm maps showing buffer zones and application areas demonstrate due diligence to certification officers.

Managing livestock waste effectively is not just an environmental responsibility – it’s a smart business decision that can strengthen your farm’s sustainability and bottom line. Throughout this guide, we’ve explored various methods and strategies that can help Alberta farmers transform waste challenges into opportunities.

By implementing comprehensive waste management practices, you’re not only complying with regulations but also creating valuable resources for your farm. Whether it’s through composting, anaerobic digestion, or strategic manure application, each approach offers unique benefits that can enhance soil health, reduce operational costs, and generate additional revenue streams.

Remember that successful waste management is an ongoing journey. Start with what works for your operation’s scale and gradually implement more advanced techniques as you build expertise. Consider connecting with local agricultural extension services and fellow farmers who have successfully implemented these practices.

The future of sustainable agriculture in Alberta depends on our collective commitment to responsible waste management. By taking action today, you’re investing in your farm’s long-term success while contributing to our province’s agricultural excellence. Let’s work together to turn livestock waste from a challenge into an asset for generations to come.