Transform agricultural waste into renewable energy and clean water through anaerobic digestion, a cornerstone of modern circular agricultural practices. This proven wastewater treatment method reduces operational costs by up to 60% while generating biogas for on-farm power generation. Canadian farmers currently process over 100,000 tonnes of organic waste annually using anaerobic digesters, creating a sustainable solution for managing livestock effluent and food processing residuals.

Anaerobic digestion stands out among wastewater treatment options by naturally breaking down organic matter in oxygen-free environments, producing energy-rich methane and nutrient-dense fertilizer as valuable by-products. This process not only addresses environmental compliance requirements but also opens new revenue streams for agricultural operations. With government incentives supporting renewable energy initiatives and increasing pressure to adopt sustainable waste management practices, anaerobic digestion offers a practical, profit-generating approach to wastewater treatment that aligns with both environmental stewardship and business growth objectives.

The Power of Anaerobic Digestion in Farm Waste Management

How Anaerobic Digestion Works on Your Farm

On your farm, anaerobic digestion works like nature’s recycling system, breaking down organic waste in an oxygen-free environment. The process happens in a sealed tank called a digester, where naturally occurring bacteria transform manure, crop residues, and other organic materials into biogas and nutrient-rich fertilizer.

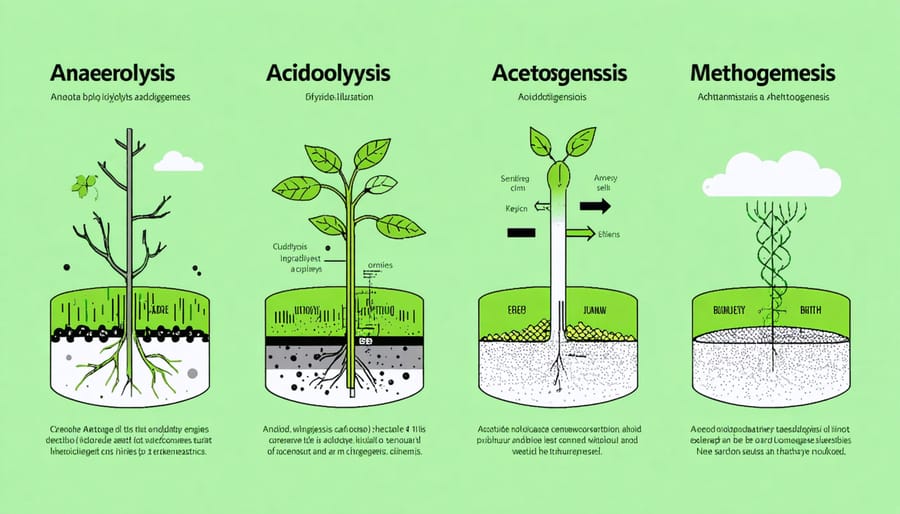

The system typically consists of three main components: a collection area where you gather your farm’s organic waste, the digester tank where the breakdown occurs, and the storage facilities for the biogas and digestate. Inside the digester, your waste goes through four stages: hydrolysis, acidogenesis, acetogenesis, and methanogenesis – each powered by different groups of bacteria working together.

The magic happens at temperatures between 35-55°C, which we maintain through insulation and heat exchangers. Your digester requires regular feeding, just like livestock, with a steady supply of organic material to keep the bacteria healthy and productive. The result? You get clean biogas for energy and high-quality liquid fertilizer that puts nutrients back into your soil, creating a sustainable cycle that benefits both your farm operations and the environment.

From Waste to Resource: The Benefits for Alberta Farmers

Alberta farmers are discovering valuable opportunities in converting agricultural waste into resources through anaerobic digestion systems. The process not only manages waste effectively but creates multiple revenue streams. Biogas production from these systems can significantly reduce energy costs, with many farms generating enough power to run their operations and sell excess electricity back to the grid.

The nutrient-rich digestate produced during treatment serves as an excellent fertilizer, reducing the need for synthetic alternatives. Farmers report saving between $15,000 and $25,000 annually on fertilizer costs alone. The treated water can be safely recycled for irrigation, helping farms maintain resilience during dry seasons.

Local success stories, like the Lethbridge Biogas facility, demonstrate how collaborative approaches between neighboring farms can make these systems more cost-effective. By pooling resources and sharing infrastructure costs, even smaller operations can access these benefits. Additionally, provincial programs supporting renewable energy initiatives often provide grants and incentives, making the initial investment more manageable for Alberta farmers looking to implement these sustainable solutions.

Setting Up Your Wastewater Treatment System

Essential Components and Design Considerations

In Alberta’s climate, designing an effective anaerobic digestion system requires careful consideration of several key components. The primary vessel, or digester tank, must be well-insulated and equipped with heating elements to maintain optimal bacterial activity during our cold winters. Most successful installations use double-walled steel or concrete tanks with spray-foam insulation.

Temperature control systems are crucial for clean energy conversion and consistent treatment performance. We recommend installing automated monitoring equipment to track temperature, pH levels, and gas production. A properly sized mixing system helps prevent settling and ensures uniform treatment throughout the tank.

The gas collection system should include moisture removal units and pressure relief valves designed for our freezing conditions. Consider installing redundant systems for critical components to prevent downtime during maintenance or extreme weather events.

Pre-treatment equipment, such as solid separation screens and grit removal systems, helps protect downstream components and optimize system performance. For operations processing dairy or livestock waste, incorporating a reception pit with sufficient capacity to handle peak loading periods is essential.

When sizing your system, factor in seasonal variations in waste production and temperature fluctuations typical in our region. Working with local suppliers familiar with Canadian agricultural requirements can ensure your system meets both environmental regulations and operational needs.

Cost-Effective Installation Strategies

Installing an anaerobic digestion system doesn’t have to break the bank. Alberta farmers can access various funding opportunities through provincial and federal programs designed to support sustainable waste management technologies. The Canadian Agricultural Partnership (CAP) offers grants covering up to 30% of eligible project costs, with maximum funding of $250,000 for individual farms.

To maximize cost-effectiveness, consider phased implementation. Start with essential components and expand the system as your operation grows. Many Alberta farmers have successfully reduced initial costs by utilizing existing infrastructure, such as repurposing unused storage tanks or incorporating the system into planned building renovations.

The Agricultural Financial Services Corporation (AFSC) provides low-interest loans specifically for environmental improvements. Their financing options can help spread the installation costs over 5-15 years, making the investment more manageable for family farms.

Local agricultural cooperatives often organize bulk purchasing programs, helping members secure better prices on equipment and installation services. Additionally, working with experienced local contractors familiar with Alberta’s climate and regulations can prevent costly mistakes and ensure optimal system performance.

Remember to factor in potential carbon credits and renewable energy incentives, which can significantly offset installation costs. The Alberta Carbon Offset System allows farmers to generate credits through methane reduction, providing an additional revenue stream while supporting environmental stewardship.

Meeting Environmental Regulations

In Canada, operating an anaerobic digestion system for wastewater treatment requires compliance with both federal and provincial regulations. For Alberta farmers, the primary regulatory framework falls under the Agricultural Operation Practices Act (AOPA), which oversees manure management and storage facilities.

Before installing an anaerobic digestion system, you’ll need to obtain necessary permits from your local Natural Resources Conservation Board (NRCB). These typically include a construction permit and an operating permit. The application process involves submitting detailed system designs, environmental impact assessments, and operational plans.

Key compliance requirements include:

– Regular water quality monitoring and reporting

– Proper containment systems for digestate

– Emergency response protocols

– Odour management strategies

– Record-keeping of system maintenance and operations

Many Alberta farmers find success by working with environmental consultants during the permit application process. The Alberta Clean Technology Industry Alliance offers resources and connects farmers with qualified professionals who understand local regulations.

Remember that regulations may vary by municipality and system size. Smaller farm-based systems often face fewer requirements than large-scale operations, but all must meet basic environmental protection standards. Your local agricultural extension office can provide guidance specific to your region and operation size.

Keep in mind that meeting these regulations isn’t just about compliance – it’s about protecting our shared water resources and maintaining good relationships with neighbouring communities.

Real Success Stories from Alberta Farms

Dairy Farm Success: The Miller Family Story

Located just outside of Red Deer, Alberta, the Miller Family Dairy Farm has become a shining example of successful anaerobic digestion implementation. In 2019, John and Sarah Miller, third-generation dairy farmers, faced mounting challenges with manure management and rising energy costs across their 200-head operation.

After careful research and consultation with local agricultural experts, the Millers invested in a 500-cubic-metre anaerobic digestion system. The initial setup cost of $750,000 was partially offset by Alberta’s Agricultural Clean Technology Program, which covered 30% of the expenses.

Within the first year of operation, the system processed approximately 4,000 tonnes of dairy waste while generating enough biogas to power their entire farm operation. The Millers report a 60% reduction in their annual energy costs and have eliminated the need for traditional lagoon storage.

“The biggest surprise was how quickly we adapted to the new system,” shares Sarah Miller. “Our staff picked up the maintenance routines within weeks, and the automated monitoring system makes daily operations straightforward.”

The farm now produces high-quality liquid fertilizer as a by-product, which they use on their 400 hectares of cropland. This has reduced their annual fertilizer costs by $25,000. Additionally, the system’s enclosed design has significantly decreased odour complaints from neighbouring properties.

The Millers regularly host farm tours for other dairy operators interested in implementing similar systems, contributing to the growing network of sustainable farming practices in Alberta.

Mixed Farming Benefits: Cedar Creek Farm’s Journey

Cedar Creek Farm in Red Deer County, Alberta, has become a shining example of how mixed farming operations can benefit from anaerobic digestion systems. Owner Sarah Thompson transformed her 400-hectare family farm into a model of sustainable waste management over the past five years.

The farm, which combines dairy operations with crop production, installed a 250-cubic-metre digester in 2019. This system processes both animal manure from their 150-head dairy herd and crop residues from their wheat and canola fields. The resulting biogas now powers 80% of the farm’s electricity needs, while the nutrient-rich digestate has reduced their annual fertilizer costs by 40%.

“The initial investment seemed daunting,” shares Thompson, “but the provincial grants and carbon credits made it feasible. Now we’re seeing returns we never expected.” Beyond the financial benefits, the farm has reduced its greenhouse gas emissions by 85 tonnes annually and virtually eliminated odour complaints from neighbouring properties.

The system’s success has attracted attention from other Alberta farmers. Cedar Creek now hosts monthly tours, sharing their experiences and helping others understand the practical aspects of implementing anaerobic digestion. Their journey demonstrates how integrating waste management solutions can create multiple revenue streams while supporting environmental stewardship.

Thompson emphasizes that their success came from careful planning and community support: “It’s about seeing waste as a resource and finding the right partners to make it work.”

Maintenance and Troubleshooting Tips

Seasonal Maintenance Schedule

A well-maintained anaerobic digestion system requires specific attention throughout Alberta’s distinct seasons. In spring (March-May), focus on checking seals and gaskets as the ground thaws, and inspect pipework for frost damage. This is also the ideal time to clean sensors and calibrate monitoring equipment.

During summer months (June-August), monitor bacterial activity closely as higher temperatures can accelerate the digestion process. Maintain optimal temperature ranges by adjusting insulation and cooling systems as needed. Schedule comprehensive system inspections when weather conditions are favourable.

Fall maintenance (September-November) should prioritize winterization preparations. Ensure all exposed pipes are properly insulated, and verify heating systems are functioning efficiently. Test emergency shutdown procedures before severe weather arrives.

Winter (December-February) requires vigilant monitoring of temperature controls and ice prevention systems. Check heating elements weekly and remove any snow accumulation from critical access points. Keep detailed maintenance logs throughout the year, noting any seasonal patterns that affect system performance.

Remember to coordinate maintenance schedules with your farm’s busy periods, particularly during spring seeding and fall harvest, to minimize operational disruptions.

Common Challenges and Solutions

Many Alberta farmers face challenges when implementing anaerobic digestion systems, but practical solutions exist for each hurdle. Temperature fluctuations during our harsh winters can affect bacterial activity, but installing proper insulation and monitoring systems helps maintain optimal conditions. A common issue is managing the right balance of organic materials – too much or too little can disrupt the process. The solution lies in careful monitoring and maintaining a consistent feeding schedule.

Foam formation and crust buildup are frequent concerns, especially when processing dairy waste. Regular maintenance and installing mechanical mixers can prevent these issues. Odour control sometimes worries farmers, particularly those near residential areas, but proper sealed systems and biofilters effectively manage this challenge.

Equipment costs can be significant, but government grants and clean energy incentives are available to help offset initial investments. Some farmers have found success by forming cooperatives to share resources and costs. Operating issues like pH imbalances can occur, but regular testing and adjusting feed ratios usually resolves these problems.

Remember, most challenges have straightforward solutions, and local agricultural extension offices can provide specific guidance for your situation.

As we’ve explored throughout this article, anaerobic digestion wastewater treatment offers tremendous potential for Canadian farmers, particularly here in Alberta. This sustainable approach not only helps manage agricultural waste effectively but also generates valuable biogas and nutrient-rich fertilizer as beneficial by-products.

The key to successful implementation lies in careful planning and community collaboration. Start by assessing your farm’s specific needs and connecting with local agricultural extension offices for guidance. Many Alberta farmers have already taken this journey, proving that the initial investment pays off through reduced operational costs and environmental benefits.

Remember that funding opportunities and technical support are available through various provincial programs. The Alberta Environmental Farm Plan and Canadian Agricultural Partnership can help offset implementation costs and provide valuable resources for getting started.

Looking ahead, the future of anaerobic digestion in Canadian agriculture is bright. As more farms adopt this technology, we’re seeing the development of regional processing facilities and cooperative arrangements that make the system more accessible to operations of all sizes.

Take the next step by reaching out to local farming associations or attending workshops about anaerobic digestion systems. Your transition to this sustainable practice contributes to both environmental stewardship and the long-term viability of Canadian agriculture. Together, we can build a more sustainable future for farming in Alberta and beyond.