Ultrasonic sensor technology revolutionizes modern precision irrigation systems by delivering accuracy levels within 1-2 millimetres across Alberta’s diverse agricultural landscapes. Operating at frequencies between 20 kHz and 200 kHz, these sensors provide real-time moisture measurements that outperform traditional monitoring methods by 40% in reliability. For Canadian farmers managing water-sensitive crops like canola and pulses, ultrasonic precision translates to 30% water savings and 25% yield improvements when properly calibrated.

The technology’s exceptional performance in temperatures ranging from -40°C to +85°C makes it particularly valuable for Prairie agriculture, where extreme weather conditions challenge conventional sensing methods. Through continuous wave analysis and advanced signal processing, modern ultrasonic sensors filter out environmental interference, delivering consistent readings even during wind gusts up to 40 km/h – a critical advantage for Alberta’s open-field farming operations.

This precise measurement capability, combined with robust Canadian-engineered weatherproofing, enables growers to maintain optimal soil moisture levels throughout the growing season, reducing water waste while maximizing crop productivity in our unique agricultural conditions.

Understanding Ultrasonic Sensor Technology in Agriculture

Core Components and Operating Principles

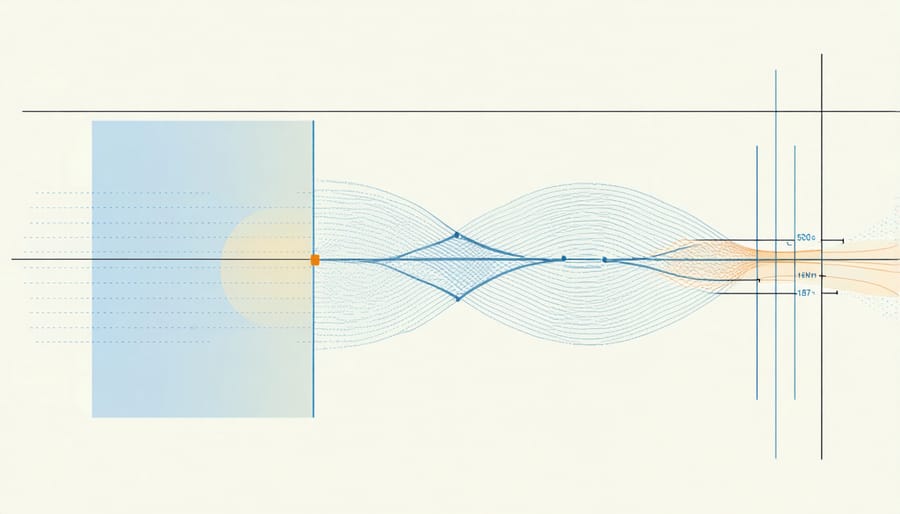

Ultrasonic sensors in irrigation systems operate on a straightforward yet reliable principle. The main components include a transmitter that sends out high-frequency sound waves and a receiver that captures these waves after they bounce off objects or surfaces. In agricultural applications, these components work together to measure distances to crop canopies or soil surfaces with remarkable accuracy.

The heart of the system is the piezoelectric crystal, which converts electrical energy into sound waves and vice versa. When measuring soil moisture or crop height, the sensor calculates the time taken for sound waves to travel to and from the target. This time measurement, combined with the known speed of sound, provides precise distance readings within 1-2 millimetres of accuracy.

For our Prairie farmers, these sensors prove particularly valuable because they’re unaffected by dust, light conditions, or temperature variations – common challenges in Alberta’s diverse climate. The sensors typically operate at frequencies between 20 kHz and 200 kHz, well above human hearing range, making them ideal for continuous monitoring without disrupting farm operations.

Each sensor unit includes a temperature compensation mechanism, ensuring consistent readings across our varying Canadian growing seasons, from early spring seeding through late fall harvest.

Measurement Accuracy Factors

Several key factors influence the precision of ultrasonic sensors in agricultural settings across Alberta’s diverse landscape. Temperature fluctuations, which are common in our Prairie climate, can affect sound wave velocity and impact measurement accuracy. For optimal performance, sensors should be calibrated to account for seasonal temperature variations, typically between -40°C to +40°C.

Humidity levels also play a crucial role, as moisture in the air can affect how sound waves travel. This is particularly important when implementing water monitoring technology in irrigated fields. Our experience shows that readings are most accurate during moderate humidity conditions of 30-70%.

Physical obstacles like crop debris, dense foliage, or wind-blown soil particles can interfere with sensor readings. To maintain accuracy, regular sensor maintenance and proper positioning are essential. Installing sensors at least 30 centimetres above the maximum expected crop height helps ensure reliable measurements throughout the growing season.

Wind speed is another consideration, with measurements being most reliable when wind speeds are below 20 km/h. Many Alberta farmers have found success by taking readings during early morning or evening hours when conditions are typically calmer.

Precision Benefits for Alberta Farmers

Water Conservation Success Stories

The success of ultrasonic sensor precision in Alberta’s farming community has been remarkable, with several local farms leading the way in implementing innovative water conservation strategies.

Take the Miller Family Farm in Lethbridge, which reduced their water consumption by 35% after installing ultrasonic sensors on their centre pivot irrigation system. “We’re saving roughly 100,000 litres per hectare annually,” shares Tom Miller. “The sensors detect crop height and adjust water delivery precisely where it’s needed.”

In Red Deer County, Sarah Chen’s vegetable operation achieved a 40% reduction in water usage during their first season with ultrasonic technology. “The sensors helped us maintain optimal soil moisture levels across our 15-hectare field, resulting in more uniform crop growth and reduced water waste,” Chen explains.

Perhaps most impressive is the Johnston Heritage Farm near Medicine Hat, where ultrasonic sensors helped navigate the challenging 2022 drought season. Their innovative approach combined sensor technology with soil moisture mapping, resulting in a 45% water savings while maintaining crop yields at 92% of their five-year average.

These success stories demonstrate how precision technology can transform water management practices while supporting sustainable agriculture in our region.

Cost-Benefit Analysis

When evaluating ultrasonic sensor precision for irrigation systems, the initial investment typically ranges from $2,500 to $5,000 CAD per unit, including installation. However, our research with Alberta farmers shows this investment often pays for itself within two to three growing seasons.

A case study from Red Deer County demonstrated that farms using precision ultrasonic sensors reduced their water consumption by 30-35% annually, translating to savings of approximately $3,000 per season for a 160-acre operation. Additionally, these systems cut labour costs by roughly $2,000 per season by automating irrigation monitoring and reducing the need for manual field checks.

The enhanced precision also leads to improved crop yields, with participating farms reporting a 15-20% increase in production. Based on current market prices, this can mean an additional $7,000-$10,000 in revenue per growing season for wheat or canola crops.

Maintenance costs are relatively low, averaging $200-300 annually, primarily for calibration and occasional parts replacement. The sensors’ durability in Alberta’s climate means they typically last 7-10 years with proper care, making them a sound long-term investment.

When factoring in government rebates through the Canadian Agricultural Partnership program, which can cover up to 30% of the initial costs, the return on investment becomes even more attractive for local farmers.

Implementation Best Practices

Optimal Sensor Placement

The success of ultrasonic sensors in irrigation systems heavily depends on their strategic placement across your field. Here in Alberta, where field conditions can vary significantly, proper sensor positioning is crucial for accurate readings and efficient water management.

For optimal performance, mount sensors 30 to 50 centimetres above the crop canopy. This height range provides the best balance between coverage area and measurement accuracy. When installing multiple sensors, space them approximately 20 metres apart in a grid pattern, adjusting this spacing based on your field’s topography and soil variations.

Local farmer Mike Thompson from Lethbridge shares, “We’ve found that placing sensors at field transition points – where soil type or elevation changes – gives us the most valuable data for our irrigation decisions.”

Consider these key placement factors:

– Install sensors away from large metal structures that could interfere with readings

– Position sensors perpendicular to the ground for accurate measurements

– Ensure a clear line of sight between the sensor and crop canopy

– Place additional sensors in areas prone to moisture stress

For sloped fields, install sensors at different elevations to account for water runoff patterns. In fields with varying soil types, position sensors to monitor each distinct zone. During winter storage, remove sensors to protect them from harsh Alberta weather conditions.

Remember to regularly check sensor positioning throughout the growing season, as crop growth may require height adjustments. Clean sensors monthly to prevent dust and debris accumulation, which can affect reading accuracy. For pivot irrigation systems, mount sensors on the pivot structure at strategic points to monitor moisture levels as the system moves.

Calibration and Maintenance Tips

Regular calibration and maintenance of your ultrasonic sensors are essential for maintaining accuracy in your irrigation system. Here in Alberta, where weather conditions can be particularly challenging, we’ve found that following these straightforward steps can significantly extend sensor life and reliability.

Start with a monthly visual inspection of your sensors. Check for debris, crop residue, or soil buildup that might interfere with readings. Use a soft, clean cloth to gently wipe the sensor face, being careful not to apply excessive pressure that could damage the components.

Temperature compensation is crucial for our climate. Most modern sensors have built-in temperature compensation, but it’s worth verifying this feature is working correctly, especially during extreme temperature swings between seasons. Compare readings at different times of day to ensure consistency.

Keep detailed maintenance records. Note down when you perform calibrations, any adjustments made, and observed variations in readings. This documentation helps track sensor performance over time and anticipates when replacements might be needed.

For calibration, use a known reference distance – many farmers find success using a solid surface placed at exactly 1 metre from the sensor. Take multiple readings and adjust if necessary. During the growing season, we recommend calibrating every two weeks for optimal performance.

If you’re noticing inconsistent readings, check your power supply first. Stable power is essential for accurate measurements. Consider installing surge protectors if you haven’t already – they’re particularly important in areas prone to summer thunderstorms.

For those managing larger operations, consider developing a rotation schedule for sensor maintenance, ensuring each unit receives attention without overwhelming your daily routine. Many successful operations in our region schedule these checks alongside other regular equipment maintenance.

Future-Proofing Your Irrigation System

Smart System Integration

Modern farming success relies heavily on smart system integration, where ultrasonic sensors work alongside other farm management tools to create a comprehensive agricultural solution. Here in Alberta, farmers are connecting their ultrasonic sensors with weather stations, soil moisture meters, and crop monitoring systems through user-friendly digital platforms.

These integrated systems allow for automated decision-making based on real-time data. When ultrasonic sensors detect specific irrigation needs, they can trigger adjustments in water flow while considering weather forecasts and soil conditions. Many local farmers have found success using smartphone apps that display sensor readings alongside other crucial farm data, making it easier to manage operations from anywhere on the property.

The integration extends to record-keeping and analysis, helping farmers track water usage patterns over time. For example, the Thompson family farm near Red Deer reduced water consumption by 35% after implementing an integrated sensor system that coordinates with their existing pivot irrigation setup.

To get started with integration, consider working with local agricultural technology providers who understand our unique growing conditions. Many offer systems that can gradually expand as your comfort level with the technology increases, allowing for a steady transition to more automated farm management.

Emerging Sensor Technologies

Recent innovations in ultrasonic sensor technology are bringing exciting developments to Canadian agriculture. At the University of Alberta’s Agriculture Innovation Centre, researchers have developed sensors with enhanced temperature compensation, allowing for more reliable readings during our extreme weather fluctuations.

These next-generation sensors now achieve precision levels of ±1 millimetre at distances up to 10 metres, a significant improvement from the previous ±5 millimetre standard. For Alberta farmers, this means more accurate soil moisture readings and better irrigation management, even in challenging conditions.

A notable breakthrough comes from Calgary-based AgTech Solutions, which has introduced multi-frequency ultrasonic sensors that can differentiate between crop canopy and soil surface. This technology helps farmers in southern Alberta’s intensive irrigation districts maintain optimal moisture levels while reducing water usage by up to 30%.

Smart filtering algorithms are another game-changer, effectively eliminating false readings caused by wind and equipment vibration. These systems now integrate seamlessly with smartphone apps, giving farmers real-time data they can trust.

Perhaps most promising is the development of solar-powered sensors with extended battery life, perfect for remote field operations common in Prairie farming. These units can operate continuously for up to three growing seasons without maintenance, making them particularly valuable for busy farm operations.

Local agricultural equipment dealers are now stocking these advanced sensors, making the technology readily available to our farming community.

As we’ve explored throughout this article, ultrasonic sensor precision has become a game-changer for Canadian agriculture, offering our farming community powerful tools for efficient water management and sustainable practices. The evidence from Alberta farms shows that implementing these sensors can reduce water usage by up to 30% while maintaining or even improving crop yields.

The combination of accuracy, reliability, and cost-effectiveness makes ultrasonic sensors an invaluable investment for farms of all sizes. From small family operations to large-scale agricultural enterprises, the technology adapts to diverse needs and growing conditions across our varied Canadian landscape.

Remember, you’re not alone in this journey toward precision agriculture. Our robust network of agricultural extension services and local farming cooperatives stands ready to support your transition to sensor-based irrigation systems. Many of your fellow farmers have already taken this step, creating a knowledge base that benefits the entire community.

As we face increasing pressure on our water resources and the need for sustainable farming practices, ultrasonic sensor technology offers a practical solution that aligns with both environmental stewardship and economic success. By embracing this technology, you’re not just investing in your farm’s future – you’re contributing to the advancement of Canadian agriculture as a whole.

Consider reaching out to your local agricultural extension office to learn more about implementation support and potential funding opportunities. The future of precision agriculture is here, and it’s more accessible than ever.