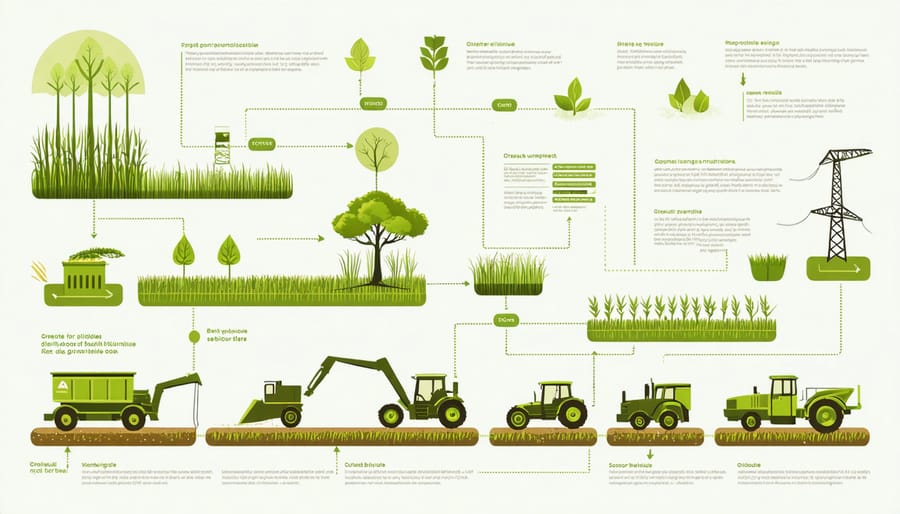

In Alberta’s evolving agricultural landscape, upcycle technology is revolutionizing how farmers transform waste into valuable resources. By repurposing agricultural byproducts into high-value materials and energy sources, local producers are cutting operational costs while championing environmental stewardship. From converting crop residue into biofuel to transforming livestock waste into premium organic fertilizers, these innovative solutions are creating new revenue streams across the prairie provinces. The latest data from Alberta Agriculture shows that farms implementing upcycling technologies have reduced waste management costs by up to 40% while generating additional income through secondary products. This practical approach to agricultural sustainability isn’t just environmentally conscious – it’s reshaping the economics of modern farming operations, offering tangible benefits for producers looking to maximize their resource efficiency and profitability in an increasingly competitive market.

Smart Bioconversion Systems Making Waves in Alberta

Automated Composting Technology

Modern smart composting systems have revolutionized how Alberta farmers manage organic waste and create nutrient-rich soil amendments. These automated systems use advanced sensors to monitor crucial parameters like temperature, moisture levels, and oxygen content, ensuring optimal decomposition conditions year-round.

A typical smart composter includes temperature probes that track heat levels across different zones, maintaining the ideal range of 55-65°C for efficient breakdown. Moisture sensors help maintain the 40-60% moisture content sweet spot, while automated aeration systems prevent anaerobic conditions that can slow decomposition and create unwanted odours.

Many Alberta farmers have reported success with systems that feature automated turning mechanisms, which reduce manual labour and ensure consistent mixing. These systems can process up to 2,000 kg of organic material weekly, converting farm waste into valuable compost within 6-8 weeks – significantly faster than traditional methods.

The technology also includes remote monitoring capabilities through smartphone apps, allowing farmers to track composting progress and receive alerts when conditions need adjustment. Some systems even integrate weather data to automatically adjust ventilation and moisture levels based on local conditions.

For smaller operations, compact units processing 500-750 kg weekly are available, making this technology accessible to family farms. The initial investment typically pays for itself within two growing seasons through reduced waste management costs and improved soil fertility.

Anaerobic Digestion Innovation

In the heart of Alberta’s agricultural landscape, innovative biogas production systems are revolutionizing how farms manage organic waste while generating renewable energy. These systems have been specifically adapted for our Canadian climate, featuring enhanced insulation and specialized heating components that maintain optimal bacterial activity even during harsh winter months.

Recent developments include dual-chamber digesters that separate hydrolysis from methanogenesis, improving efficiency by up to 30% compared to traditional single-chamber systems. At the Morgan Family Farm near Red Deer, their upgraded anaerobic digestion system processes 50 tonnes of agricultural waste daily, generating enough energy to power their entire operation plus 200 nearby homes.

The latest technology incorporates smart monitoring systems that use AI to optimize bacterial conditions and biogas output. These systems automatically adjust temperature, pH levels, and feeding rates based on real-time data, reducing the need for constant manual oversight. For smaller operations, compact modular units are now available, starting at 10-tonne capacity, making this technology accessible to family farms.

Local success stories demonstrate that farms implementing these systems typically see a return on investment within 4-6 years through energy savings and carbon credit programs. Additionally, the resulting digestate provides a nutrient-rich fertilizer that many farmers report has improved their soil health and crop yields significantly.

From Crop Residue to Revenue

Biofuel Production Systems

Modern biofuel production systems are revolutionizing how Alberta farmers approach agricultural waste management, forming a crucial component of circular agricultural practices. These innovative systems transform crop residues, livestock manure, and other farm by-products into valuable energy sources, creating new revenue streams while reducing environmental impact.

Leading the way is anaerobic digestion technology, which has gained significant traction among Alberta’s farming community. These systems break down organic waste in oxygen-free environments, producing biogas that can be used for heating, electricity generation, or compressed natural gas for farm vehicles. Local success stories include the Lethbridge Biogas facility, which processes over 120,000 tonnes of agricultural waste annually.

Cellulosic ethanol production represents another promising avenue, particularly for grain farmers dealing with excess straw and chaff. Using enzymatic processes, these systems convert tough plant materials into bioethanol, which can be blended with conventional fuels or used directly in modified engines. Several Alberta farms have implemented small-scale cellulosic systems, reporting fuel cost reductions of up to 30%.

Emerging pyrolysis technologies are also showing promise, converting agricultural residues into bio-oil and biochar. The bio-oil serves as a renewable fuel source, while biochar can be used to enhance soil quality. Prairie farmers using these systems report improved soil fertility while generating additional income from fuel production.

These technologies are becoming more accessible through government grants and cooperative purchasing programs, making them viable options for farms of various sizes. Local agricultural extension services offer support in selecting and implementing the most suitable biofuel system based on individual farm needs and waste streams.

Value-Added Products

Modern agricultural waste can be transformed into valuable products through innovative upcycling technologies, creating new revenue streams for Canadian farmers. Here in Alberta, several farmers are already implementing these solutions with impressive results.

One popular approach is converting crop residue into biocomposite materials. For example, flax straw, traditionally a disposal challenge, can be processed into high-strength materials for manufacturing everything from automotive parts to eco-friendly furniture. Local success stories include the Thompson family farm near Red Deer, which partners with a manufacturing facility to convert their wheat straw into packaging materials.

Anaerobic digestion technology offers another promising avenue, transforming livestock manure and organic waste into both renewable energy and nutrient-rich fertilizer. The resulting bio-fertilizer can be sold to neighbouring farms or garden centres, while excess biogas can power farm operations or be sold back to the grid.

Innovative processing systems can turn food processing waste into valuable ingredients. Potato peelings from processing facilities can be converted into dietary fibre supplements, while fruit pulp becomes natural food coloring. The Calgary-based Prairie Organic Processing Initiative helps farmers connect with food manufacturers to create these value-added products.

Many Alberta farmers are also exploring mushroom cultivation using agricultural waste as growing substrate. This method transforms wheat straw or corn stalks into profitable gourmet mushroom operations, with some farmers reporting returns of up to $30 per kilogram for specialty varieties.

Before implementing these technologies, consider factors like initial investment costs, available waste streams, and local market demand. The Alberta Farm Waste Management Association offers guidance and connects farmers with technology providers and potential buyers for upcycled products.

Real Success Stories: Alberta Farmers Leading the Way

The Miller Farm Story

The Miller Farm story stands as a shining example of innovative waste management in Alberta’s agricultural sector. In 2019, John and Sarah Miller faced mounting costs from managing waste on their 200-head dairy operation near Red Deer. Rather than viewing their farm’s organic waste as a burden, they saw an opportunity for transformation.

The Millers invested in a biodigester system that converts manure and expired feed into biogas and nutrient-rich fertilizer. Within the first year, they reduced their waste disposal costs by 65% while generating enough energy to power their entire milking operation. The high-quality organic fertilizer produced by the system allowed them to cut their commercial fertilizer purchases by half.

“We used to spend thousands managing waste. Now that same waste generates revenue,” explains Sarah Miller. Their system processes 12 tonnes of organic material daily, producing approximately 250 kilowatts of electricity and 10 tonnes of organic fertilizer per week.

The success prompted neighboring farms to adopt similar systems, creating a informal waste-to-resource network in central Alberta. The Millers now host monthly tours for local farmers, sharing their experiences and helping others understand the practical aspects of implementing upcycling technology.

The Miller Farm demonstrates how innovative thinking and strategic investment in upcycling technology can transform traditional waste management challenges into profitable opportunities while promoting environmental sustainability.

Collective Success in Red Deer County

Red Deer County’s success in agricultural waste upcycling stands as a shining example of what’s possible when communities work together. In 2021, local farmers formed the Red Deer Agricultural Waste Coalition, bringing together 47 farming operations to share resources and implement innovative upcycling solutions.

The coalition’s first major initiative involved establishing a centralized composting facility that transforms agricultural waste into high-grade fertilizer. Local farmer Sarah McKenzie, who helped spearhead the project, reports that participating farms have reduced their waste disposal costs by an average of 35% while creating a valuable new revenue stream.

“What makes our approach unique is that we’re not just sharing equipment and facilities,” explains McKenzie. “We’re sharing knowledge and supporting each other through the learning curve of adopting new technologies.”

The coalition also implemented a mobile processing unit that travels between farms, converting crop residues into biofuel pellets. This community-based approach has made expensive technology accessible to smaller operations that couldn’t afford it individually.

Regular workshops and demonstration days have become a cornerstone of the program, where farmers can learn from each other’s experiences and troubleshoot challenges together. The initiative has already inspired similar programs in neighbouring counties, with Lacombe County launching their own coalition in early 2023.

Getting Started with Waste Upcycling Technology

Assessment and Planning

Before implementing upcycle technology on your farm, it’s essential to conduct a thorough assessment of your current operations and future needs. Start by documenting your existing waste streams and identifying potential opportunities for transforming agricultural waste into valuable resources.

Create an inventory of your farm’s equipment, infrastructure, and available storage space. Consider seasonal variations in waste production and potential processing capacity. Factor in your farm’s energy consumption patterns and current disposal costs, as these will help determine the economic viability of different upcycling solutions.

Connect with local agricultural extension services and fellow farmers who have implemented similar technologies. Their experiences can provide valuable insights into what works best in Alberta’s unique climate and conditions. Consider forming cooperatives or partnerships with neighboring farms to share resources and maximize efficiency.

Evaluate your farm’s financial resources and explore available grants or funding programs through provincial initiatives. The Agricultural Financial Services Corporation (AFSC) and other local organizations often provide support for sustainable farming practices.

Document your goals, whether they’re reducing disposal costs, creating additional revenue streams, or meeting environmental targets. This will help you prioritize which upcycling technologies to implement first and create a realistic timeline for integration into your existing operations.

Available Support and Resources

Several support networks and resources are available to Alberta farmers interested in implementing upcycle technology. The Canadian Agricultural Partnership (CAP) offers grants of up to $50,000 for sustainable agriculture initiatives, including technology upgrades and waste reduction projects. Local agricultural societies across Alberta provide technical assistance and mentorship programs to help farmers navigate new technological implementations.

The Alberta Clean Technology Industry Alliance (ACTIA) maintains a network of experts who offer free consultations to farmers exploring upcycle technologies. Their services include feasibility studies and connection to equipment suppliers. The Environmental Stewardship and Climate Change Producer Program specifically supports projects that reduce environmental impact through innovative technology adoption.

Farmers can also access support through regional agricultural research associations, which regularly host workshops and field demonstrations. The Alberta Farm Sustainability Extension Working Group (AFSEWG) provides one-on-one coaching and detailed resource guides for implementing new technologies.

For hands-on assistance, the Agricultural Technology Centre in Lethbridge offers testing facilities and technical expertise. They maintain a database of successful upcycling projects and can connect farmers with peers who have implemented similar systems. Additionally, several municipal waste management facilities provide reduced rates for agricultural businesses implementing waste-to-resource technologies.

Contact your local agricultural fieldman or district office to learn more about available funding and support programs in your area.

As Alberta’s farming community continues to embrace sustainable practices, upcycle technology presents a promising path forward. By implementing these innovative solutions, we can transform agricultural waste into valuable resources while reducing our environmental footprint and operating costs. From converting crop residue into biofuels to repurposing livestock waste for energy production, the opportunities are both practical and profitable. Remember, successful implementation starts with small steps – consider joining local farming cooperatives or attending workshops to learn from peers who have already adopted these technologies. Together, we can build a more sustainable future for Canadian agriculture while maintaining our position as global leaders in agricultural innovation. Reach out to your local agricultural extension office today to explore how upcycle technology can benefit your farm operations.