Understand that variable renewables—solar and wind power—generate electricity inconsistently based on weather conditions, but this doesn’t disqualify them from powering your farm operations effectively. Calculate your baseline energy needs during overnight hours and cloudy periods to determine minimum battery storage capacity required, typically 12-24 hours of reserve power for critical systems like livestock ventilation, water pumping, and refrigeration.

Pair intermittent sources with your existing grid connection or diesel generators to create hybrid systems that automatically switch between power sources, maintaining reliability while reducing fuel costs by 40-70 percent during peak generation hours. Many Alberta operations running green energy systems discover their solar panels produce excess electricity during summer afternoons precisely when irrigation demands peak, creating natural alignment between supply and farm activities.

Design your renewable infrastructure around predictable daily patterns rather than seeking 100 percent energy independence immediately. Solar output follows reliable sunrise-to-sunset curves, while wind resources in southern Alberta typically strengthen during spring and fall when heating or cooling loads increase. Time energy-intensive tasks like grain drying, shop work, and equipment charging to coincide with high-generation periods, effectively using your farm operations as flexible load management.

The variability challenge often concerns farmers evaluating first-time renewable investments, but understanding these fluctuations allows strategic planning rather than presenting insurmountable obstacles. Modern monitoring systems provide real-time generation data and weather forecasts, enabling you to schedule operations days in advance. Storage technology costs have dropped 60 percent since 2015, making battery backup increasingly affordable for bridging generation gaps. Variable doesn’t mean unreliable when you match system design to your specific operational requirements and energy consumption patterns throughout different seasons.

What Makes Renewable Energy ‘Variable’ (And Why It Matters for Farms)

The Sun Doesn’t Always Shine: Understanding Solar Variability

Solar energy in Alberta follows predictable patterns that directly affect how you can use it on your farm. Understanding these patterns helps you plan which operations work well with solar and when you’ll need backup power.

During summer months, Alberta enjoys 16 to 17 hours of daylight, making solar panels highly productive from May through August. A typical 10-kilowatt solar array on an Alberta farm might generate 50 to 60 kilowatt-hours daily in June, but only 15 to 20 kilowatt-hours in December when daylight drops to just 7 hours. This seasonal swing is more dramatic than in southern regions, so planning becomes essential.

Daily fluctuations matter too. On a clear day, your solar output peaks between 11 AM and 2 PM. Cloud cover can reduce production by 50 to 80 percent within minutes. For time-flexible operations like running irrigation pumps or charging equipment batteries, this variability works fine. You simply operate when the sun provides power.

However, operations requiring consistent energy at specific times face challenges. Grain dryers running during harvest can’t wait for sunny weather. Barn heating needs power during cold mornings regardless of cloud cover. Ventilation fans must run on schedule to maintain livestock health.

The solution isn’t abandoning solar but understanding its rhythm. Many Alberta farmers successfully use solar for daytime operations while maintaining grid connections or generators for critical evening and winter loads. This hybrid approach maximizes your renewable energy use while ensuring reliable power when operations demand it.

Wind Patterns on the Prairies

Alberta’s prairie winds follow predictable patterns that can work surprisingly well with your farm’s energy needs. Understanding these patterns helps you make informed decisions about wind power integration.

On the prairies, wind speeds typically increase during late morning and peak in the afternoon, often between 2 PM and 6 PM. This timing aligns reasonably well with daytime operations like grain drying, irrigation pumping, and shop work. However, winds also tend to be stronger during cooler months—October through April—when your energy demands for heating and grain handling peak, but irrigation needs drop.

Seasonal variations are significant. Spring and winter generally deliver the strongest, most consistent winds across Alberta farmland, with average speeds ranging from 15 to 25 kilometers per hour. Summer months see calmer conditions, averaging 10 to 18 kilometers per hour, which doesn’t always match peak irrigation season demands. This seasonal mismatch is worth considering when planning your renewable energy system.

Nighttime winds can be valuable too. While they’re often lighter than daytime breezes, they still generate power when your farm’s electricity consumption typically drops. This overnight generation can charge battery storage systems or offset baseline loads like refrigeration and security lighting.

The variability challenge becomes clear when you compare these patterns to common farm operations. Grain drying might need consistent power for 12 to 18 hours straight, but wind speeds can fluctuate significantly within that timeframe. That’s where hybrid systems combining wind with solar or battery storage become practical solutions, smoothing out the natural ups and downs of prairie winds.

Matching Variable Energy Production to Farm Work Cycles

High-Energy Tasks You Can Schedule Around the Sun

The sun’s predictable daily pattern makes solar energy remarkably plannable once you understand your system’s output curve. Most solar installations reach peak production between 10 a.m. and 3 p.m., creating an ideal window for your most energy-intensive operations.

Water pumping stands out as the most flexible high-energy task on most farms. Whether you’re filling livestock troughs or powering irrigation systems, these operations rarely need to happen at specific times. A grain farmer near Lethbridge shifted all irrigation pumping to midday hours, reducing his grid dependency by 60 percent during growing season. Consider installing larger storage tanks or reservoirs to hold water pumped during peak solar hours for use throughout the day and night.

Equipment charging offers another straightforward scheduling opportunity. Electric UTVs, tools, and battery packs can easily charge during sunny hours rather than overnight when you’d be drawing from the grid or depleting battery storage. Set up a dedicated charging station in a sunny location and make midday charging part of your routine.

Grain processing operations like augering, drying, and cleaning work well when scheduled around solar availability. One mixed operation in central Alberta runs their grain dryer exclusively during peak production hours in fall, storing dried grain for later transport. The key is having adequate bin space to stage grain before and after processing.

Shop activities including welding, machinery maintenance, and wood cutting also adapt well to solar schedules. Many farmers report that planning repair work for sunny days has become second nature, maximizing their solar investment while maintaining operational flexibility. The practice requires some planning adjustments initially but quickly becomes routine.

When the Wind Blows: Overnight and Seasonal Operations

Wind energy shines when you match its availability to flexible tasks that don’t need power at specific times. Many farm operations fall into this category, making them perfect candidates for direct wind power without expensive battery systems.

Ventilation systems in livestock barns represent an ideal application. While animals need continuous airflow, you can often run exhaust fans more aggressively when wind speeds are high, then reduce ventilation during calm periods without compromising animal welfare. Saskatchewan producer James Thiessen runs his poultry barn ventilation directly from a 10 kW wind turbine, using the grid only as backup during extended calm periods.

Well pumps offer another excellent match. Most farms have water storage capacity, whether in livestock tanks, irrigation reservoirs, or pressure systems. Program your wind-powered pump to fill storage whenever wind is available. A 300-metre deep well pump drawing 2 kW can fill a 10,000-litre tank in about three hours of good wind, providing several days of reserve capacity.

Battery charging for electric fencing, equipment, or utility vehicles works naturally with variable wind. Charge controllers prevent overcharging while capturing available energy whenever the turbine spins. Southern Alberta rancher Maria Santos charges her side-by-side and fencing batteries exclusively from wind, eliminating weekly trips to the shop for charging.

Grain drying and aeration systems can also operate opportunistically. Run your aeration fans during windy periods, taking advantage of free power while achieving the same preservation results. The key is building adequate storage capacity to buffer the intermittent generation, turning wind variability from a challenge into a practical advantage.

Solving the Storage Problem: Battery Systems for Alberta Farms

Right-Sizing Your Battery Bank

Calculating your battery storage needs doesn’t require an engineering degree, just an honest assessment of your farm’s energy patterns. Start by identifying which operations must continue during periods when your solar panels or wind turbines aren’t generating power. A 200-acre grain operation in central Alberta found they needed enough storage to cover evening livestock feeding, milking equipment, and critical grain bin ventilation for approximately 4-6 hours daily during winter months.

The basic formula is straightforward: multiply your essential load (in kilowatts) by the hours of backup you need. If your critical equipment draws 8 kW and you need 5 hours of coverage, that’s 40 kWh of storage capacity. However, Saskatchewan farmer James Chen recommends adding a 25-30% buffer to account for battery aging and extreme weather performance drops. His 160-acre mixed operation initially installed 50 kWh of lithium-ion storage but wishes he’d started with 65 kWh after experiencing his first winter with the system.

Cost considerations matter significantly for medium-sized operations. Current lithium-ion battery systems in Canada range from $800-1,200 per kWh installed, meaning a 50 kWh system represents a $40,000-60,000 investment before incentives. Lead-acid batteries cost roughly half that amount but require replacement every 5-7 years versus 10-15 years for lithium systems.

Many Alberta farms are finding success with modular approaches, starting with smaller battery banks covering only the most critical loads, then expanding as budget allows and as they better understand their actual usage patterns. This phased approach reduces upfront risk while building practical knowledge about what your operation truly needs during low-generation periods.

Beyond Batteries: Alternative Storage Methods

Battery systems aren’t the only way to store renewable energy on your farm. Several alternative methods can provide reliable backup power without the hefty price tag of lithium batteries.

Thermal storage offers a practical solution, especially for livestock operations. Insulated water tanks can store heat generated during sunny periods, maintaining warm water for dairy barns or livestock facilities overnight. Some Alberta farmers are pairing solar thermal collectors with heavily insulated 1,000-2,000 litre tanks, keeping water temperatures stable for 12-24 hours without additional heating.

Gravity-fed water systems represent another creative approach. When wind or solar energy is abundant, pumps fill elevated storage tanks. Gravity then delivers water pressure when renewable generation drops, eliminating the need for constant pumping. These smart water systems work particularly well for irrigation and livestock watering.

Compressed air energy storage is gaining attention for larger operations. Excess electricity compresses air into tanks or underground caverns, which later powers pneumatic tools or generates electricity through expansion turbines.

Ice storage systems freeze water during off-peak hours, then use that thermal mass for cooling during peak demand periods. This approach suits operations requiring refrigeration for produce storage or dairy cooling, shifting energy consumption to match renewable production patterns rather than fighting against them.

Hybrid Systems: Combining Variable Renewables with Backup Power

Grid-Connected Systems That Work in Rural Alberta

Alberta’s grid-connected renewable systems offer farmers a practical path forward, combining the reliability of provincial infrastructure with clean energy generation. The Micro-Generation Regulation allows farms to install systems up to 5 megawatts, generating power for on-site use while feeding excess electricity back to the grid.

Net metering creates a two-way energy relationship. When your solar panels or wind turbines produce more power than you need, the excess flows to the grid, spinning your meter backward. During periods of low renewable production—cloudy days or calm nights—you draw from the grid seamlessly. Your utility bill reflects the net difference, with credits typically rolling over monthly and settled annually.

Connection requirements vary by utility provider, but generally include certified equipment, professional installation, and liability insurance of at least two million dollars. EPCOR, FortisAlberta, and ATCO each maintain specific technical standards for interconnection. Application processing typically takes 60 to 90 days, though straightforward installations often move faster.

Financial implications prove compelling for many operations. Grid backup eliminates the substantial cost of battery storage while maintaining power reliability for critical systems like milking equipment or irrigation pumps. The investment in grid-connected solar typically pays back within 8 to 12 years through reduced electricity costs and net metering credits.

Consider Brandon Thiessen’s operation near Olds, where a 50-kilowatt solar array paired with grid connection supports his smart barn solutions while generating approximately 3,500 dollars annually in net metering credits. This hybrid approach delivers renewable benefits without compromising operational continuity.

When to Keep Your Generator (And When to Use It Less)

Your existing generator isn’t obsolete when you add renewable energy—it’s your insurance policy. The smart approach is keeping it as backup while letting solar panels or wind turbines handle your everyday power needs.

Run the numbers on your current fuel costs. Many Alberta farmers spend $200-500 monthly on diesel or propane for generators. By switching to renewables for 70-80% of your energy needs, you’ll dramatically cut those expenses while still having reliable backup during extended cloudy periods or equipment maintenance.

Maintenance matters too. Generators left idle for months can develop issues, so plan to run yours monthly for 30 minutes under load. This keeps seals lubricated and prevents fuel system problems. Mark it on your calendar alongside other equipment checks.

The transition period typically looks like this: use your generator heavily during installation and system testing, then gradually reduce runtime as you build confidence in your renewable setup. Most operators find they eventually run their backup generator only 10-20 hours monthly instead of several hours daily.

Consider fuel storage carefully. Diesel degrades after 6-12 months without stabilizers, while propane stores indefinitely. Choose your backup fuel type based on how often you’ll actually use it.

Real Numbers from Alberta Farms: What Variable Renewables Actually Cost and Save

Let me show you what variable renewables actually cost on working Alberta farms, with numbers you can verify and lessons straight from farmers who’ve made the investment.

The Robertson Family Farm near Lethbridge installed a 25-kilowatt solar array in 2021 paired with a 10-kilowatt wind turbine. Their upfront cost was $68,000 after federal and provincial incentives reduced the initial $92,000 price tag. “We were nervous about the investment,” admits Dave Robertson, “but our monthly power bills dropped from around $850 to about $320.” That’s $6,360 in annual savings. At that rate, their payback period sits at roughly 10.7 years, though Dave notes their system should last 25 to 30 years with proper maintenance.

What made their system work was timing energy-intensive operations around production peaks. “We run our grain dryers and equipment during sunny, windy periods when we’re generating the most power,” Dave explains. They also installed a modest 15-kilowatt-hour battery system for $8,500, which stores enough energy to handle evening chores and basic lighting.

Further north, the Chen family operates a mixed livestock and grain operation near Olds. They took a different approach, installing only solar panels (no wind component) with a larger battery bank. Their 30-kilowatt solar system cost $54,000 installed, with batteries adding another $18,000. “We generate about 75 percent of our power needs from April through September,” says Maria Chen. “Winter production drops to maybe 40 percent, so we still rely on grid power, but our annual costs dropped by about $4,800.” Their payback timeline is longer at roughly 15 years, but Maria emphasizes the non-financial benefits: “We sleep better knowing we’re less vulnerable to power outages during critical times like calving season.”

The most important lesson from both families? Start smaller than you think you need. Dave wishes they’d begun with just solar panels before adding wind. “We would have learned the system better and understood our actual usage patterns before committing to the full setup.”

Both farms track their production through monitoring apps, which revealed surprising patterns. Peak generation often occurs during midday when basic operations need less power, while morning and evening demand spikes require either battery storage or grid power. This reality check helps set realistic expectations.

Maintenance costs have been minimal for both operations, averaging around $400 annually for inspections and occasional panel cleaning. Neither farm has experienced major component failures yet, though both budget approximately $2,000 yearly for potential repairs as systems age.

The consensus? Variable renewables work for Alberta farms, but success requires honest assessment of your energy patterns, willingness to adapt operations slightly, and patience with payback timelines that span a decade or more.

Getting Started: Your First Steps Toward Variable Renewable Integration

Taking the first step toward variable renewable integration doesn’t need to feel overwhelming. Here’s a practical roadmap to get you started on your farm.

Begin with an energy audit. Understanding your current electricity consumption patterns helps identify which operations could benefit most from renewable power. Track your usage across seasons—you’ll likely notice peak demands during harvest, irrigation, or livestock feeding times. This baseline data becomes invaluable when sizing your system and planning for storage needs.

Finding qualified installers in Alberta is your next priority. Look for professionals certified by the Canadian Standards Association who have experience with agricultural installations. Ask for references from other farming operations, and don’t hesitate to visit completed projects. A quality installer will assess your site conditions, discuss realistic production estimates, and explain maintenance requirements without overselling system capabilities.

Alberta farmers have access to several financial supports. The Canadian Agricultural Partnership offers cost-share funding for energy efficiency projects, while the Canada Greener Homes Grant provides up to $5,000 for renewable energy installations. Some rural municipalities offer additional property tax incentives for renewable systems. Contact Alberta Agriculture and Irrigation’s regional offices for current program details and application deadlines.

Consider starting small with scalable systems. A 5-10 kilowatt solar array paired with battery storage can power specific operations like livestock watering systems, shop equipment, or grain handling facilities. This approach lets you gain practical experience with smart technology integration and energy management before expanding to larger installations.

Connect with other farmers already using variable renewables. Local agricultural societies and sustainability networks provide valuable peer-to-peer learning opportunities. Their real-world insights about system performance, seasonal challenges, and operational adjustments can save you time and money while building confidence in your renewable energy journey.

Integrating variable renewables into your Alberta farming operation doesn’t require a perfect system from day one. The reality is that even modest renewable energy integration can deliver meaningful results for your bottom line and operational resilience. Farms across the province are already demonstrating that you don’t need to power everything with solar or wind to see substantial benefits.

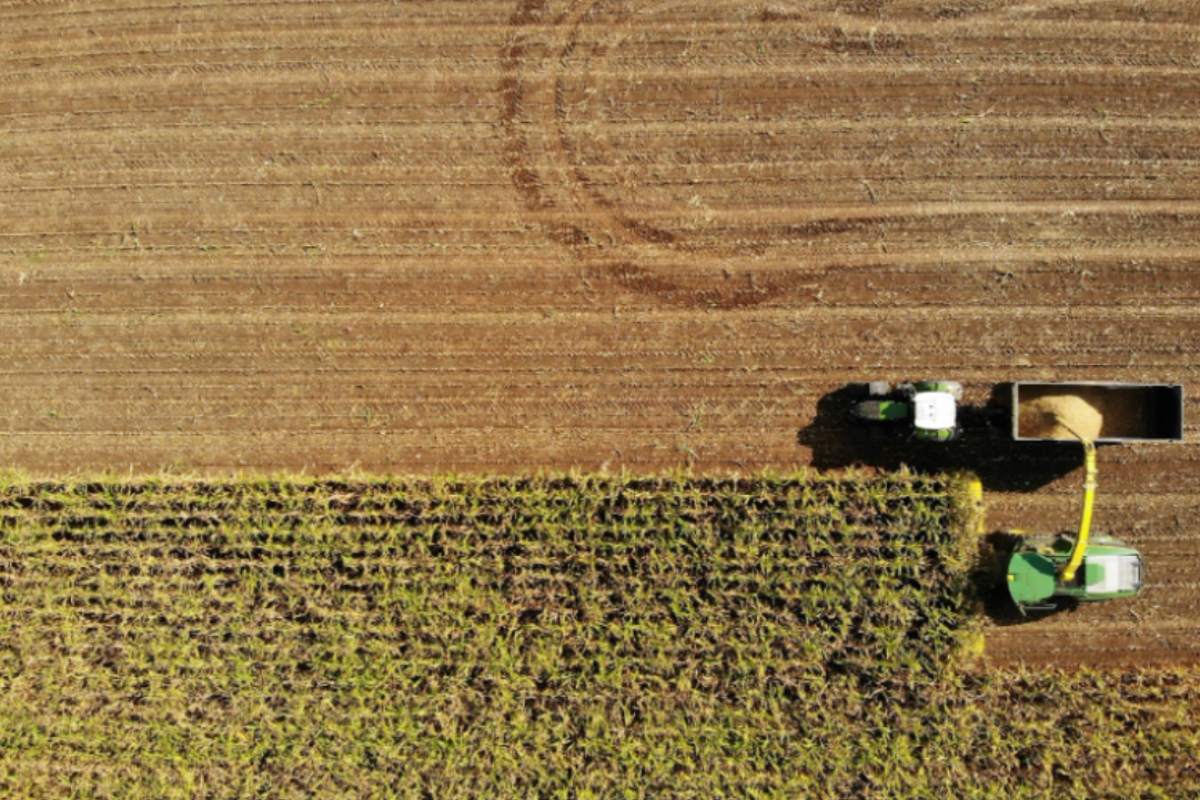

Start where it makes sense for your specific operation. Many Alberta farmers begin with a single application, whether that’s powering irrigation pumps during sunny summer months, running grain dryers with wind energy, or maintaining livestock water systems with hybrid solutions. These targeted implementations allow you to learn the technology, understand your energy patterns, and build confidence before expanding.

The technology supporting variable renewables continues improving while costs decrease. Battery storage systems that seemed prohibitively expensive five years ago are now within reach for mid-sized operations. Grid connection policies are evolving to better support farm-scale renewable installations. You’re entering this space at an increasingly favorable time.

Your next steps can be straightforward. Request an energy audit to identify your highest-value opportunities. Connect with other farmers who’ve already installed renewable systems to learn from their experiences. Explore available provincial and federal incentive programs that can offset initial investments. Consider starting with a pilot project that addresses a specific, high-cost energy need on your farm.

Remember that transitioning to variable renewables is a journey, not a destination. Each farm’s path will look different based on operations, geography, and goals. The important part is taking that first step toward energy independence and long-term sustainability. Your investment today positions your operation for greater resilience and profitability in the years ahead.