Transform agricultural waste into clean, renewable energy through sustainable farm energy systems that power Canadian farms year-round. Biomass energy harnesses the stored solar energy in organic materials – from crop residues to livestock manure – converting them into heat, electricity, and biofuels through proven conversion technologies.

For Alberta farmers, biomass presents a powerful opportunity to reduce energy costs while contributing to Canada’s renewable energy goals. Modern biomass systems achieve up to 90% efficiency when converting agricultural waste into usable energy, providing reliable power for everything from grain drying to greenhouse heating.

Unlike fossil fuels, biomass creates a closed carbon cycle where the CO2 released during energy production is recaptured by the next season’s crops. This renewable process, combined with the abundance of agricultural biomass resources across Canadian farmland, makes it an increasingly attractive option for farms seeking energy independence and environmental sustainability.

What Makes Biomass Energy Work on Canadian Farms

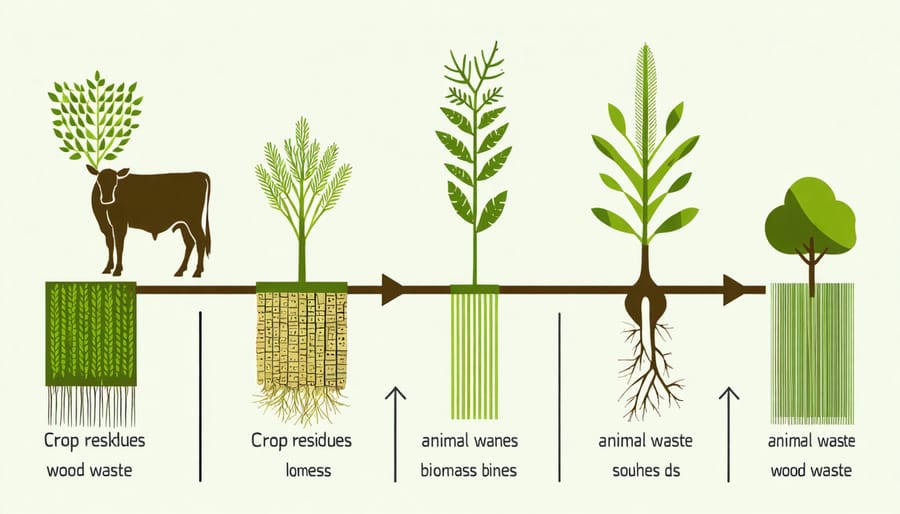

Common Farm Biomass Sources

Canadian farms are rich in biomass resources that can be converted into valuable energy. Crop residues, including wheat straw, corn stalks, and barley husks, make up the largest portion of available farm biomass. After harvest, these materials can be collected and processed instead of being left in the field or burned.

Animal waste from livestock operations provides another significant source of biomass. Dairy and beef cattle, pig, and poultry operations generate manure that can be processed in anaerobic digesters to produce biogas. Many Alberta farmers are already using this method to power their operations and reduce waste management costs.

Wood waste from windbreaks and woodlots, including prunings and fallen branches, can be chipped and used as biomass fuel. Additionally, dedicated energy crops like switchgrass and miscanthus, which grow well in Canadian climates, can be planted specifically for biomass production without competing with food crops.

Purpose-grown oilseed crops such as canola can serve dual purposes – the seeds for oil production and the remaining plant material for biomass energy. Even spoiled or low-grade grains unsuitable for market can be redirected as biomass fuel, ensuring nothing goes to waste on the farm.

Energy Conversion Methods

Canadian farmers have several effective methods to convert agricultural biomass into usable energy. Direct combustion is the most straightforward approach, where dried biomass like corn stalks or wood chips is burned in specially designed furnaces to generate heat for buildings or grain drying operations.

Anaerobic digestion offers another popular option, particularly for livestock operations. This process breaks down manure and organic waste in oxygen-free environments to produce biogas, which can power generators or heat farm buildings. Many Alberta dairy farms have successfully implemented this technology, reducing energy costs while managing waste effectively.

Gasification transforms solid biomass into a combustible gas by heating it with limited oxygen. This syngas can fuel engines or generate electricity. While less common, some larger operations use this method to power their facilities.

For crop residues, pelletization creates dense, easily stored fuel that burns efficiently in automated systems. Several Prairie region farms have adopted this approach, converting wheat straw and other agricultural byproducts into a valuable energy resource.

These conversion methods can be scaled to suit different farm sizes and needs, making biomass energy accessible to operations of all sizes.

Setting Up Your Farm’s Biomass System

Collection and Storage

Proper collection and storage of biomass materials are crucial for maintaining a reliable energy supply throughout the year. Here in Alberta, many farmers have developed efficient systems for gathering crop residues, wood waste, and other organic materials during harvest season.

For crop residues like wheat straw and corn stalks, timing is everything. Collect these materials when moisture content is below 20% to prevent decomposition and maintain energy value. Using modern balers with moisture sensors helps ensure optimal conditions. Round bales should be stored on elevated surfaces and covered with weatherproof tarps or in dedicated storage structures to prevent moisture damage.

Wood waste requires different handling techniques. Many Alberta farmers partner with local sawmills and forestry operations to source wood chips and sawdust. These materials should be stored in well-ventilated bins or covered piles to maintain proper moisture levels between 25-35%.

Purpose-built storage facilities are worth the investment for large-scale operations. These structures should have concrete floors to prevent ground moisture, good ventilation to avoid moisture buildup, and easy access for loading equipment. Consider installing temperature monitoring systems to detect any concerning heat buildup in stored materials.

Local farmer Dave Thompson from Red Deer County shares, “We built our storage facility with multiple bays to separate different types of biomass. This helps us maintain quality and makes it easier to manage our feed stock throughout the year.”

Processing Equipment

To convert biomass into usable energy, you’ll need specific equipment that matches your farm’s scale and type of biomass material. The most common setup includes a biomass storage system, usually a covered facility to keep materials dry, and a preprocessing unit for size reduction and material handling.

For small to medium-sized operations, a hammer mill or chipper is essential for breaking down woody biomass into manageable pieces. These machines typically process 2-5 tonnes per hour, perfect for most Alberta farm operations. Conveyor systems and augers help move materials efficiently through the process.

The heart of any biomass system is the conversion unit. For heat production, you might use a biomass boiler or furnace, which can range from 100 kW to several megawatts in capacity. For biogas production, you’ll need an anaerobic digester with a capacity typically between 1,000-5,000 cubic metres, depending on your farm size.

Material handling equipment like front-end loaders and skid steers are crucial for daily operations. You’ll also need monitoring equipment to track moisture content, temperature, and emissions. Many Alberta farmers find that adding a pelletizer can make biomass storage and handling more efficient, though this is optional depending on your needs.

Remember to choose equipment that’s certified for Canadian winter conditions and meets local safety standards. Many suppliers offer equipment packages specifically designed for our climate and farming conditions.

Integration with Existing Farm Systems

Integrating biomass energy systems into your existing farm operations doesn’t have to be complicated. Many Alberta farmers have successfully adapted their current infrastructure to accommodate biomass processing and energy generation, helping to boost farm productivity while reducing waste.

Start by identifying your farm’s primary biomass sources – whether that’s crop residue, livestock manure, or wood waste. Most farms can connect biomass processing equipment to existing storage facilities and handling systems. For example, if you’re already collecting crop residue, adding a biomass collection point to your regular harvesting routine requires minimal adjustment.

The key is to establish a seamless flow between your biomass source, processing area, and energy generation system. Many farmers find success by positioning their biomass processing units near existing equipment storage areas or barn complexes. This proximity reduces transportation costs and maximizes efficiency.

Consider installing conveyor systems or adapting current grain handling equipment to move biomass material. Modern biomass systems can often integrate with existing electrical infrastructure, requiring only modest modifications to your current power distribution setup.

Remember to consult with local agricultural extension services and experienced biomass system installers who understand Alberta’s unique farming conditions. They can help you develop an integration plan that works with your farm’s specific layout and operational needs.

Real Success Stories: Alberta Farmers Using Biomass

Davidson Family Farm’s Heat Recovery System

Located just outside of Red Deer, Alberta, the Davidson Family Farm has become a shining example of successful Alberta farm energy solutions through their innovative biomass heat recovery system. In 2019, the Davidsons installed a state-of-the-art biomass boiler that processes agricultural waste from their 800-hectare mixed farming operation.

The system converts wheat straw, corn stalks, and wood waste into heat for their greenhouse operations and barn facilities. By implementing a closed-loop heat distribution network, the Davidsons have reduced their annual heating costs by 65% while maintaining optimal growing conditions year-round.

“The initial investment was significant,” shares John Davidson, “but the system paid for itself within three years through energy savings and government incentives. Plus, we’re putting our waste to good use.”

The farm’s biomass system processes approximately 450 tonnes of agricultural residue annually, generating enough heat to warm 2,000 square metres of greenhouse space and three livestock barns. The automated feed system requires minimal daily maintenance, typically less than 30 minutes.

What makes the Davidson’s system particularly effective is their innovative heat storage solution, using a 50,000-litre water tank that maintains consistent temperatures even during Alberta’s coldest months. This success has inspired neighbouring farms to explore similar sustainable energy options, contributing to a growing network of biomass-powered agricultural operations in Central Alberta.

Red Deer Valley Cooperative’s Shared Biomass Initiative

In the heart of Alberta’s Red Deer Valley, a groundbreaking cooperative initiative is transforming agricultural waste into sustainable energy. The Red Deer Valley Cooperative, comprising 47 local farms, launched their shared biomass facility in 2019, demonstrating how rural communities can collaborate to create renewable energy solutions.

The facility processes approximately 12,000 tonnes of agricultural residue annually, including crop stubble, wood waste from shelterbelts, and livestock bedding. This waste material, which previously posed disposal challenges for farmers, now powers a 2.5-megawatt biomass plant that provides heating for eight greenhouse operations and electricity for 1,200 rural homes.

“Our cooperative approach made this project feasible for everyone involved,” explains Sarah Thompson, the initiative’s coordinator. “Individual farms couldn’t justify the investment alone, but together, we’ve created something truly sustainable.”

The project has generated significant economic benefits, reducing energy costs for participating farms by an average of 35% and creating twelve full-time local jobs. Moreover, the initiative has strengthened community bonds, with farmers sharing equipment and expertise in biomass collection and processing.

The cooperative’s success has inspired similar projects across Alberta, with three other farming communities currently developing their own shared biomass facilities. The Red Deer Valley model proves that when rural communities combine resources and knowledge, sustainable energy solutions become both practical and profitable.

Economic and Environmental Benefits

Cost Savings and ROI

When evaluating biomass energy systems, many Alberta farmers find that their renewable energy investments typically pay for themselves within 3-7 years, depending on system size and current energy costs. For a medium-sized farm operation using 500,000 kWh annually, switching to biomass can reduce energy expenses by 40-60%, translating to approximately $25,000-$35,000 in yearly savings.

The financial benefits extend beyond direct energy costs. Farmers using agricultural waste for biomass reduce disposal expenses and can sometimes generate additional income by selling excess energy back to the grid. According to recent case studies in Southern Alberta, farms implementing biomass systems have reported total operational cost reductions of 30-45% within the first year.

Government incentives and grants, such as the Canadian Agricultural Clean Technology Program, can offset initial installation costs by up to 50%. When combined with carbon credit programs, these incentives significantly improve the return on investment. Local success stories, like the Morrison Family Farm in Red Deer County, demonstrate how integrating biomass energy systems has led to both environmental sustainability and substantial cost savings, with their system achieving full payback in just 4.5 years.

Environmental Impact

Biomass energy offers significant environmental benefits, particularly for Canadian farming operations. When managed sustainably, biomass systems create a closed carbon cycle – plants absorb CO2 during growth, which is later released during energy production, resulting in near-neutral carbon emissions. This represents a marked improvement over fossil fuels, with studies showing up to 90% reduction in greenhouse gas emissions when replacing traditional energy sources.

For Alberta farmers, implementing biomass energy systems helps reduce agricultural waste while providing renewable energy. Crop residues, which might otherwise be burned in fields, can be converted into valuable energy resources. This practice not only minimizes air pollution from open burning but also returns nutrients to the soil through the application of biochar, a beneficial byproduct of biomass processing.

Local success stories demonstrate the sustainability benefits. The Thompson family farm near Red Deer reduced their carbon footprint by 65% after switching to a biomass heating system for their greenhouse operations. Additionally, biomass energy projects create opportunities for carbon credits, providing farmers with additional revenue streams while contributing to Canada’s climate action goals.

The environmental advantages extend beyond emissions reduction, including improved soil health, reduced landfill waste, and enhanced biodiversity through sustainable biomass crop rotation.

As we’ve explored throughout this guide, biomass energy offers Canadian farmers a sustainable way to manage agricultural waste while generating valuable energy resources. The potential for reducing operational costs while contributing to environmental stewardship makes biomass systems an attractive option for many Alberta farming operations.

Remember that success with biomass energy starts with assessing your farm’s specific resources and needs. Consider starting small with a pilot project, perhaps converting crop residue or animal waste into biofuel for heating farm buildings. Connect with local agricultural extension offices and fellow farmers who have implemented biomass systems to learn from their experiences.

Funding opportunities through provincial and federal clean energy initiatives can help offset initial setup costs. The Alberta Renewable Energy Program and Canadian Agricultural Partnership offer support for farmers transitioning to renewable energy solutions.

Take the next step by conducting a biomass resource assessment on your farm and consulting with renewable energy specialists who understand local agricultural conditions. By joining the growing community of Canadian farmers embracing biomass energy, you’re not just investing in your operation’s future – you’re contributing to a more sustainable agricultural sector for generations to come.