Biodiverse farming transforms conventional agricultural operations into resilient ecosystems that produce food while supporting native species, improving soil health, and buffering against increasingly unpredictable weather patterns. For Alberta farmers facing longer droughts, sudden frosts, and intense rainfall events, integrating biodiversity isn’t just an environmental choice—it’s becoming an economic necessity that protects yields and reduces input costs.

The challenge lies in implementing biodiversity strategies without sacrificing productive land or investing in permanent infrastructure that locks you into one approach. Biodegradable farm polystructures—temporary frameworks made from natural materials like bamboo, hemp fiber, and biodegradable plastics—offer a practical middle ground. These structures create protected microclimates for diverse plantings, extend growing seasons for beneficial insects and secondary crops, and break down naturally when your operation needs to shift.

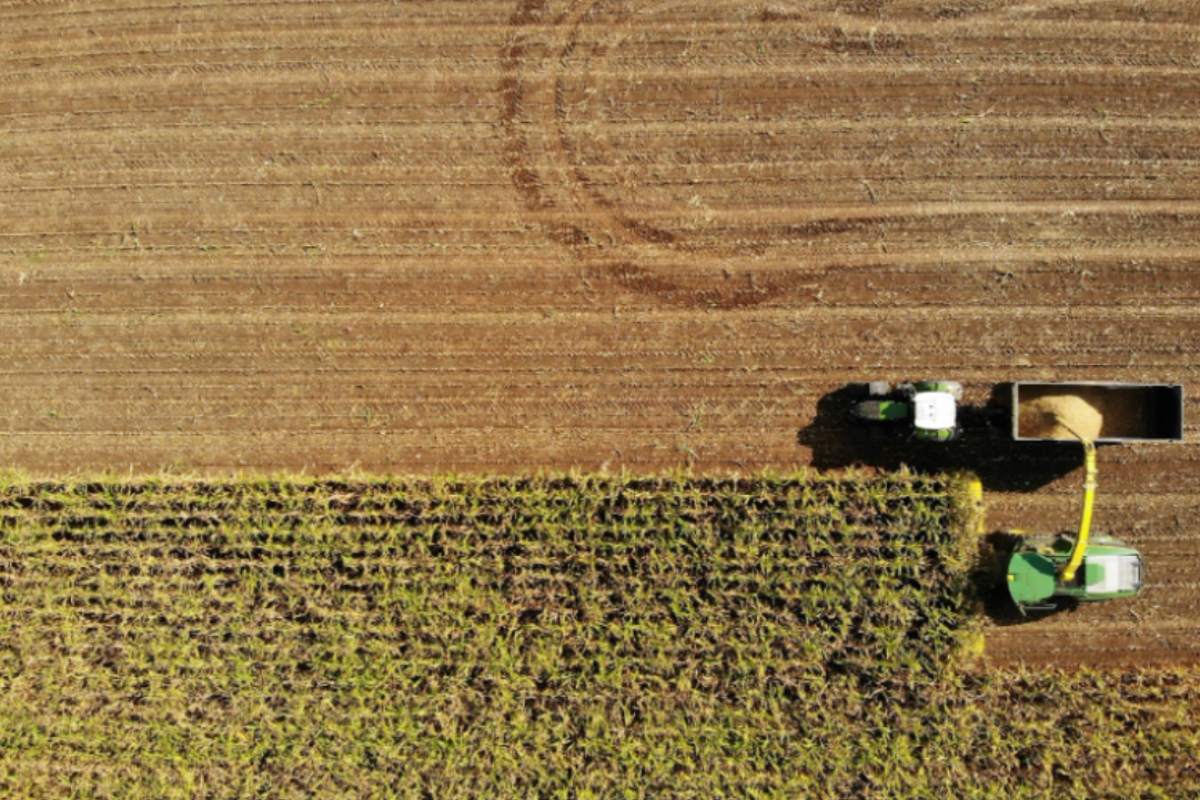

Prairie farmers are already seeing results. Near Lethbridge, mixed operations use seasonal hoop structures with biodegradable covers to establish pollinator corridors between fields, increasing canola yields by 12-18 percent while the structures decompose into soil amendments within two years. In central Alberta, cattle ranchers deploy temporary windbreaks made from woven willow and hemp composite panels that shelter native plant restoration sites, reducing wind erosion and creating habitat zones that don’t require permanent land retirement.

This approach works because it matches the adaptive nature of biodiverse systems with practical farm management. You’re not committing to permanent changes or expensive installations. Instead, you’re testing biodiversity interventions that support climate resilience while maintaining operational flexibility—and when the structures break down, they leave behind organic matter that enriches rather than pollutes your soil.

What Are Biodegradable Farm Polystructures?

Materials and Composition

Biodegradable farm polystructures rely on innovative materials that break down naturally without harming your soil ecosystem. Most modern structures use plant-based biopolymers derived from cornstarch, sugarcane, or potato starch, combined with natural fiber reinforcements like hemp, flax, or jute. These materials typically decompose within 12 to 36 months under prairie conditions, depending on moisture levels and microbial activity in your soil.

The decomposition process actually enriches your soil rather than contaminating it. As these structures break down, they release organic carbon and nutrients that feed beneficial microorganisms and improve soil structure. Alberta researchers at the University of Lethbridge have documented increased earthworm populations and enhanced water retention in fields where biodegradable structures have decomposed.

Unlike conventional plastics that fragment into harmful microplastics, certified biodegradable materials meeting ASTM D6400 or EN 13432 standards convert fully to carbon dioxide, water, and biomass. A 100-square-meter biodegradable hoop house covering, for example, adds approximately 15 to 20 kilograms of organic matter to your soil once decomposed. This closed-loop approach aligns perfectly with regenerative farming principles while supporting the diverse soil life essential for climate-resilient agriculture. Many Alberta producers report noticeably improved soil texture in areas where these materials have naturally integrated into their fields.

Types of Polystructures for Alberta Farms

Alberta’s growing season and prairie climate create unique opportunities for biodegradable polystructures that support both biodiversity and crop production. Understanding which structures work best in your operation can help you enhance resilience while reducing plastic waste.

Temporary row covers offer your first line of defense against early season frosts and intense UV exposure. These lightweight fabrics, often made from plant-based polymers, extend your growing season by 2-4 weeks while allowing beneficial insects access to your crops. They’re particularly effective for market gardens and small-scale vegetable operations transitioning to more diverse cropping systems.

Hoop houses provide season extension on a larger scale. Unlike permanent greenhouses, biodegradable hoop structures use frames with compostable covering materials that typically last 2-3 seasons. They create microclimates that support diverse plantings while protecting against hail—a significant concern across the prairies. Many Alberta farmers report success using these for high-value crops like tomatoes, peppers, and salad greens alongside native pollinator plants.

Windbreaks constructed from biodegradable mesh reduce wind speeds by up to 60 percent, protecting both crops and beneficial insect populations. These structures work particularly well when combined with living hedgerows, providing immediate protection while permanent vegetation establishes.

Erosion control netting made from materials like jute or hemp helps stabilize soil on slopes and newly seeded areas. This protects waterways while allowing native plants to establish, creating habitat corridors that connect different areas of your farm. These networks are essential for supporting the movement of pollinators and other beneficial species across your landscape.

The Connection Between Polystructures and Biodiverse Farming

Creating Microclimates for Diverse Crops

Biodegradable polystructures create distinct microclimates that dramatically expand what you can grow on your farm, even in Alberta’s challenging climate. By adjusting ventilation, shade coverage, and moisture levels within these structures, you can create optimal conditions for crops that typically struggle in our region.

Take the example of Three Hills producer Janet Morrison, who uses seasonal polystructures to extend her growing season by six weeks on both ends. “We’re now successfully growing heat-loving crops like peppers and eggplant alongside native wildflowers that support our pollinator populations,” she explains. Her structures feature roll-up sides for temperature control and can be easily relocated between seasons.

These protected environments also allow you to integrate climate-ready crops with pollinator-friendly species that might otherwise be vulnerable to late spring frosts or early fall freezes. By dedicating sections of your polystructure to native flowering plants like purple coneflower or wild bergamot, you create year-round habitat for beneficial insects while diversifying your operation.

The key is understanding that different crops need different conditions. Leafy greens thrive in cooler, more humid sections, while tomatoes prefer warmer, drier air. Strategic placement within your structure, combined with simple adjustments to ventilation and shade cloth density, lets you optimize conditions for each plant group. This approach means you’re not just extending seasons but genuinely expanding the diversity of what’s viable on your land.

Supporting Beneficial Insects and Wildlife

Temporary polystructures create valuable habitat corridors that support the ecosystem services essential to productive farms. When positioned strategically across your operation, these biodegradable structures offer shelter for beneficial insects like ground beetles, parasitic wasps, and native pollinators that control pest populations naturally.

During a conversation with Dr. Sarah Chen, an entomologist working with Alberta producers, she emphasized that “even temporary windbreaks can increase beneficial insect populations by 40 to 60 percent within a single growing season.” These structures provide crucial overwintering sites and microclimates that protect predatory insects during temperature extremes.

The beauty of biodegradable materials lies in their ability to decompose naturally, returning organic matter to the soil while maintaining habitat value throughout their functional lifespan. Unlike permanent structures requiring removal, these materials break down into nutrients that feed soil organisms, completing a beneficial cycle.

Prairie farms implementing polystructure corridors report measurable increases in bird populations, particularly insect-eating species that further reduce pest pressure. One central Alberta grain producer noted improved pollination rates in adjacent field margins after installing temporary hedgerow structures, demonstrating how strategic placement amplifies benefits. These habitat features work alongside your existing shelterbelts and field margins, creating connected ecosystems that enhance your farm’s natural resilience.

Soil Health and Decomposition Benefits

Biodegradable materials used in farm polystructures offer significant advantages for soil health when compared to conventional plastic alternatives. As these materials naturally break down at the end of their useful life, they return valuable organic matter to the soil rather than contributing to plastic contamination. This decomposition process enriches soil with carbon and nutrients while supporting diverse microbial communities essential for healthy crop production.

Research from Alberta’s agricultural systems shows that biodegradable mulches and temporary structures can improve soil structure and water retention over time. The breakdown process feeds beneficial bacteria and fungi, creating a more resilient soil microbiome that better supports plant growth and disease resistance. This biological activity also enhances moisture management capabilities naturally.

For prairie farmers, eliminating plastic residue from fields means reducing long-term contamination risks and supporting cleaner agricultural operations. Unlike conventional plastics that fragment into microplastics and persist for decades, properly certified biodegradable materials integrate seamlessly into soil ecosystems. This approach aligns with regenerative farming principles while maintaining the practical benefits of protective structures for extending growing seasons and adapting to climate variability.

Climate Adaptation Benefits for Alberta Farms

Protection from Extreme Weather Events

Alberta’s unpredictable weather patterns pose significant challenges for farmers, but biodiverse farming with polystructures offers practical protection. These temporary structures work alongside strategic plant diversity to create multiple layers of defense against extreme conditions.

Polystructures effectively shield vulnerable crops from hail damage, which costs Alberta farmers millions annually. The fabric canopies absorb impact while allowing necessary light and air circulation. When combined with diverse crop heights and windbreaks, they reduce wind erosion by up to 60 percent compared to monoculture systems. The structures create microclimates that moderate temperature swings, protecting crops from late spring and early fall frosts that can devastate single-variety plantings.

Saskatchewan farmer Tom Hendricks shared his experience: “After installing polystructures over my mixed vegetable beds, I extended my growing season by three weeks on each end. The diverse plantings underneath create their own insulation layer, and I’ve noticed my soil stays warmer longer into fall.”

These climate adaptation technologies complement biodiversity rather than replace it. Taller companion plants within the structures provide additional wind protection for lower-growing crops, while varied root depths improve water infiltration during heavy precipitation events. The combination addresses multiple weather threats simultaneously, making your operation more resilient without compromising environmental values.

Water Conservation and Management

Biodiverse farming systems naturally enhance water efficiency across your operation. When you integrate diverse plantings—including deep-rooted perennials, ground covers, and varied crop species—you create a living mulch system that reduces soil evaporation by up to 40% compared to monocultures. This vegetative diversity also improves soil structure and organic matter content, boosting moisture retention capacity by 20-30%.

Alberta producer Sarah Chen from Leduc County reports her diversified vegetable operation now requires 25% less irrigation since implementing mixed cover crops and hedgerow plantings. “The soil stays damper longer, and we’re seeing healthier crops during dry spells,” she notes.

Strategic windbreaks using native shrubs and trees further reduce evaporation while creating wildlife habitat. Position these biodegradable polystructure-supported plantings perpendicular to prevailing winds for maximum effect. The structures provide temporary support while permanent vegetation establishes.

Consider integrating water conservation strategies like swales and bioswales within your diverse plantings. These landscape features slow water movement, allowing greater soil infiltration while supporting varied plant communities.

Dr. Michael Bartholomew from Olds College emphasizes that “biodiversity and water efficiency are inseparable—each plant species contributes differently to the water cycle, creating resilience during both drought and excess moisture events.”

Temperature Regulation

Biodegradable polystructures work like natural windbreaks and tree canopies, creating protective microclimates that help you manage temperature extremes throughout the growing season. During cooler months, these temporary structures trap solar heat and block cold winds, warming the soil and air around your crops by 3-5°C. This buffering effect lets you start planting 2-3 weeks earlier in spring and extend your harvest well into fall.

In summer, strategically placed structures provide critical shade for heat-sensitive crops and beneficial insects. Alberta grower Maria Chen reports that her biodegradable shade tunnels reduced crop stress during the 2021 heat dome, protecting pollinator populations that might otherwise have abandoned her fields. The structures also maintain soil moisture by reducing evaporation rates by up to 30%.

The temperature regulation extends your viable growing season by 4-6 weeks total, allowing you to diversify crop rotations and support a wider range of beneficial species. This extended season means more flowering periods for pollinators and increased habitat availability for predatory insects that control pests naturally, strengthening your farm’s overall biodiversity while improving yields.

Real Results: Alberta Farmers Making It Work

Case Study: Mixed Vegetable Operation Near Edmonton

Sarah Chen operates a 12-hectare mixed vegetable operation just outside Edmonton, where unpredictable spring weather and late frosts have always challenged her early planting schedules. Three years ago, she decided to experiment with biodegradable row covers made from corn-based polymers to extend her growing season while protecting soil biodiversity.

The results exceeded her expectations. “We used to lose about 20 percent of our early lettuce and brassica crops to frost damage,” Sarah explains. “With the biodegradable covers, we’ve cut those losses to under 5 percent while advancing our harvest dates by nearly two weeks.” This earlier market entry translates to premium pricing when local demand for fresh greens is highest.

Beyond frost protection, Sarah noticed unexpected benefits for crop diversity. The covers created microclimates that allowed her to trial heat-loving crops like peppers and eggplants that previously struggled in Alberta’s short season. She’s now successfully growing eight additional vegetable varieties compared to before implementing the covers.

The economic impact proved compelling. While the biodegradable covers cost approximately $800 per hectare more than conventional plastic initially, Sarah eliminated disposal fees and reduced labour costs associated with removing and storing traditional materials. Her calculation shows a break-even point in the second season, with continued savings afterward as the covers decompose directly into the soil, actually improving organic matter content.

Most importantly for Sarah’s long-term vision, soil testing revealed increased earthworm populations and microbial activity in covered areas, validating her commitment to farming practices that work with natural systems rather than against them.

Case Study: Regenerative Ranch in Southern Alberta

When the Morrison family’s 400-hectare ranch near Lethbridge faced increasing wind erosion and declining pollinator populations, they turned to an integrated approach combining biodegradable windbreaks with native prairie plantings. Over three growing seasons, their experience demonstrates how temporary structures can support long-term ecological goals.

The operation started by installing biodegradable jute mesh windbreaks along their most vulnerable field edges, standing 2 metres high and stretching across 800 metres of exposed cropland. “We chose jute because it would naturally decompose while our permanent plantings established,” explains Sarah Morrison, who manages the ranch with her husband. “The material reduced wind speed by 60 percent in the first year, giving our native plants the protection they needed to take root.”

Between the windbreak rows, the Morrisons planted 12-metre-wide strips featuring native species like purple prairie clover, wild bergamot, and blue grama grass. These strips now serve dual purposes: the deep-rooted perennials anchor soil year-round, while flowering plants support declining pollinator populations essential for their canola and pulse crops.

By year three, the biodegradable barriers had decomposed completely, leaving behind healthy native plantings that now function as living windbreaks. Soil tests showed organic matter increased by 1.8 percent in adjacent fields, while the family documented a 40 percent reduction in topsoil loss during spring winds.

The economic results proved equally compelling. Despite initial establishment costs of $3,200 per hectare for materials and native seed, the Morrisons recovered their investment through improved yields in sheltered crop areas and reduced input costs from better soil retention. Their success has inspired five neighbouring operations to adopt similar approaches.

Practical Implementation: Getting Started on Your Farm

Assessing Your Farm’s Needs

Start by walking your property to identify vulnerable areas that need protection from extreme weather. Look for spots where soil erosion occurs, crops suffer heat stress, or wind damage is common—these are prime candidates for biodiverse polystructures. Take note of existing microclimates and consider how temporary structures could extend your growing season or shelter beneficial insects.

Next, evaluate your current crop diversity. Are you rotating legumes that fix nitrogen? Could you introduce companion plantings under protective structures? Many Alberta farmers have successfully added pollinator-friendly species alongside cash crops, creating habitats that support both production and ecosystem health.

Consider what structure types align with your goals. High tunnels work well for season extension and protecting tender crops, while insect hotels and hedgerow supports foster beneficial species. Think about your farm’s specific challenges—whether that’s spring frost, summer heat waves, or early fall freezes.

Talk with neighbouring farmers about what’s worked for them. Central Alberta producer Sarah Chen found that strategically placed windbreaks reduced crop stress by 30 percent while providing habitat corridors. Your local agricultural extension office can also help assess soil conditions and recommend biodiversity enhancements suited to your region’s climate patterns.

Sourcing Materials in Canada

Finding biodegradable polystructure materials in Canada has become increasingly straightforward as demand from environmentally-conscious farmers grows. Several Canadian suppliers now specialize in climate-adapted agricultural solutions specifically designed for our northern conditions.

Prairie-based companies like Agri-Cover Solutions in Saskatchewan and Green Farm Structures in Manitoba have emerged as reliable sources for biodegradable greenhouse films and tunnel covers. These suppliers offer materials with UV stabilization rated for Canadian weather patterns, typically lasting 3-5 growing seasons before composting naturally. Alberta farmers can also connect with regional distributors through provincial agricultural trade shows or the Alberta Farmers’ Co-op network.

Cost comparisons reveal that biodegradable polystructures initially run 15-20% higher than conventional plastic options. A standard 9-metre by 30-metre biodegradable tunnel costs approximately $2,800-$3,200, compared to $2,300-$2,600 for traditional plastic. However, disposal costs tell a different story. Conventional plastics require transportation and landfill fees averaging $150-$300 per structure, while biodegradable materials break down on-site, eliminating these expenses.

Many Canadian suppliers now offer volume discounts for farm operations purchasing multiple units, and some provinces provide grants that offset the initial investment difference. Ontario’s Environmental Farm Plan, for example, covers up to 50% of biodegradable material costs, with similar programs emerging in other provinces. This financial support makes the transition increasingly accessible for operations of all sizes.

Installation and Maintenance Tips

Timing your installation correctly makes all the difference with biodegradable polystructures. In Alberta, aim for spring installation after the last frost but before peak growing season—typically late April to early May. This gives structures time to settle before summer storms arrive.

Prairie winds require extra attention when securing these temporary structures. Anchor points should be installed every 2 to 3 metres along the base, using biodegradable stakes driven at least 30 centimetres into the ground. For lighter materials, consider adding rock or sandbag weights at corners and midpoints. Randy Peterson, a sustainable farming consultant from Lacombe, recommends checking all anchor points after the first significant wind event to identify any weak spots before they become problems.

Seasonal maintenance keeps your structures functional throughout their intended lifespan. After spring runoff, inspect for water damage or settling. Mid-summer checks should focus on UV degradation and structural integrity during peak heat. Before winter, remove any debris accumulation and verify that snow load won’t compromise the framework—most biodegradable structures are designed to break down within one to three growing seasons, so plan accordingly.

Keep detailed records of installation dates and material types. This helps you understand decomposition rates specific to your microclimate and soil conditions, making future installations more efficient. Regular walkthroughs every three to four weeks catch small issues before they require major intervention.

Expert Insights on Long-Term Sustainability

Leading voices in Canadian agriculture are increasingly optimistic about the role of biodegradable structures in supporting long-term farm sustainability, particularly as climate pressures intensify across the prairies.

Dr. Sarah Chen, a soil health researcher at the University of Alberta, emphasizes the circular benefits of biodegradable polystructures. “What we’re seeing in our research plots is fascinating. These structures provide immediate climate protection during the growing season, then break down to contribute organic matter back to the soil. It’s a win-win that addresses both short-term production needs and long-term soil health goals,” she explains. Her team has documented measurable improvements in soil carbon content and microbial activity in fields where biodegradable materials have been integrated into farm management practices.

From a biodiversity perspective, Dr. Michael Kowalski, an ecologist working with Prairie Conservation Action Plans, highlights the unexpected benefits. “Traditional permanent structures can create barriers to wildlife movement and disrupt pollinator pathways. Biodegradable seasonal structures offer protection when crops need it most, then disappear, allowing natural systems to function freely during critical periods for native species,” he notes. His research tracking pollinator populations around farms using temporary structures shows marked increases in beneficial insect diversity compared to conventional farming operations.

Agricultural economist Janet Thorsen brings a practical perspective to the conversation. “The economic sustainability piece is crucial for adoption. We’re now seeing five to seven-year payback periods for farmers who invest in quality biodegradable structures, particularly when you factor in improved yields, reduced plastic disposal costs, and potential premium pricing for sustainably grown products,” she reports. Her analysis of Alberta farms demonstrates that early adopters are experiencing both environmental and financial returns.

These experts agree that biodegradable farming structures represent more than just a trend—they’re a practical tool for building resilient, productive farming systems that work with natural processes rather than against them.

Economic Considerations and Support Programs

Transitioning to biodiverse farming with biodegradable polystructures requires financial planning, but the investment often pays dividends through improved yields and reduced input costs. Understanding both the upfront expenses and available support programs helps make this transition more accessible for Canadian producers.

Initial costs for biodegradable polystructures typically range from $15 to $40 per square metre, depending on size and specifications. A standard 100-square-metre hoop house using biodegradable materials might cost $2,000 to $4,000, including basic infrastructure. While this represents a notable investment, these structures often last 3-5 seasons before requiring replacement, and the biodegradable nature eliminates disposal fees that conventional plastic structures incur—typically $200 to $500 per structure in Alberta.

Long-term financial benefits emerge through multiple channels. Producers implementing biodiverse farming systems report 15-30% reductions in pesticide costs as beneficial insects and natural predators establish themselves. Extended growing seasons under protective structures increase revenue potential by $3,000 to $8,000 annually for small-scale operations. Jason Weber, an agricultural economist at the University of Alberta, notes that “farmers adopting integrated biodiversity approaches see breakeven within 2-3 years, with compounding returns as soil health improves.”

Canadian farmers have access to substantial support for sustainable agriculture infrastructure. The Canadian Agricultural Partnership offers cost-share funding up to 50% for environmental projects, including biodiversity enhancement initiatives. Agriculture and Agri-Food Canada’s AgriAssurance Program provides up to $15,000 per project for climate adaptation measures.

Alberta-specific programs include the On-Farm Climate Action Fund, which covers up to 75% of eligible expenses for projects reducing greenhouse gas emissions. The Alberta Community Resilience Program supports infrastructure improvements that enhance climate adaptation, with grants ranging from $5,000 to $100,000.

Several Alberta producers have successfully leveraged these programs. Green Haven Farms near Lacombe secured $8,500 through the Canadian Agricultural Partnership to establish biodegradable hoop houses and pollinator habitat, recovering their investment within 18 months through increased vegetable sales and reduced input costs. The Growing Forward 2 program has similarly supported dozens of prairie operations transitioning to biodiversity-focused production systems, demonstrating that financial barriers need not prevent adoption of these climate-resilient practices.

Biodegradable polystructures offer Alberta farmers a realistic pathway to address two of agriculture’s most pressing challenges simultaneously: declining biodiversity and increasing climate unpredictability. This isn’t about abandoning conventional practices overnight or making dramatic changes that strain your operation financially. Instead, it represents an evolution in how we think about farm infrastructure—moving from permanent, petroleum-based structures toward flexible, soil-enriching alternatives that work with natural systems rather than against them.

The evidence from farms across our province shows that these structures deliver measurable benefits. They create microclimates that protect crops during unexpected frost events, support beneficial insect populations that reduce pest pressure, and eventually break down to improve soil health. For operations already feeling the effects of shorter growing seasons, late spring snowfalls, or summer heat waves, this technology addresses immediate climate adaptation needs while building long-term ecological resilience.

The economic case is equally compelling. When you factor in reduced chemical inputs, improved pollination, extended growing seasons, and the elimination of disposal costs, biodegradable polystructures often pencil out favorably compared to traditional options—especially when provincial and federal support programs are leveraged strategically.

You don’t need to transform your entire operation to get started. Choose one high-value crop area or a single field trial. Document your results—track yields, pest pressure, and input costs. Connect with groups like the Alberta Soil Health Network or your regional sustainable agriculture associations. Many farmers have found that sharing experiences and troubleshooting challenges together makes the transition smoother and builds confidence in these emerging practices.

Climate adaptation on Canadian farms happens one thoughtful decision at a time. Biodegradable polystructures give you a practical tool to protect your livelihood while contributing to healthier agricultural landscapes for the next generation.